4x4 tarpaulin vs. Water-Resistant Tarps: Which one is right for you

When selecting the ideal protective covering for your specific needs, understanding the fundamental differences between various tarp types becomes crucial for making an informed decision. The choice between a 4x4 tarpaulin and water-resistant tarps involves evaluating multiple factors including durability, application requirements, weather resistance, and long-term performance expectations. While both options serve protective purposes, their construction materials, manufacturing processes, and intended applications differ significantly. A 4x4 tarpaulin, typically constructed from high-quality polyethylene (PE) materials, offers superior structural integrity and versatility compared to standard water-resistant alternatives. The dimensions and material composition of 4x4 tarpaulin products make them particularly suitable for heavy-duty applications where consistent protection against environmental elements is essential. Understanding these distinctions helps consumers identify which solution best aligns with their specific coverage requirements, budget considerations, and performance expectations.

Material Composition and Construction Quality

Polyethylene vs. Alternative Materials in 4x4 Tarpaulin Manufacturing

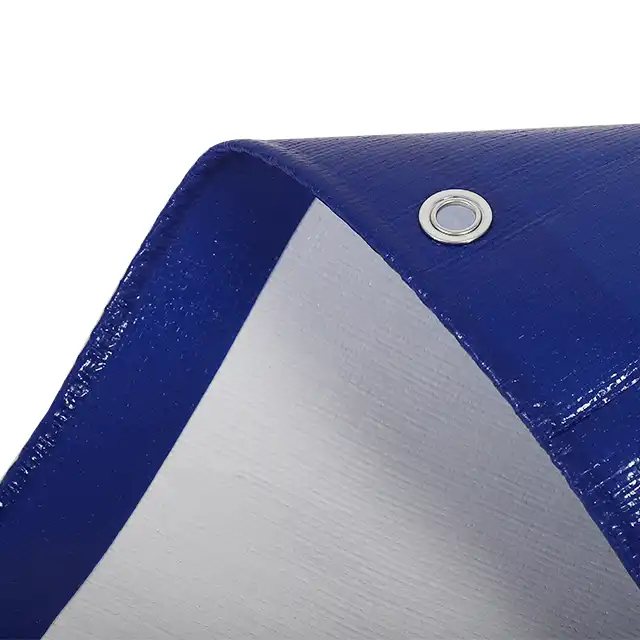

The construction of 4x4 tarpaulin products relies heavily on advanced polyethylene manufacturing techniques that ensure superior performance characteristics compared to traditional water-resistant materials. High-quality PE tarpaulins undergo specialized processing using wire drawing lines and water-jet looms, creating a fabric structure with exceptional tensile strength and dimensional stability. The 4x4 tarpaulin manufacturing process involves extruding polyethylene yarns ranging from 400D to 2500D, allowing manufacturers to customize the material density according to specific application requirements. This controlled yarn thickness directly impacts the final product's durability, weight, and protective capabilities. Unlike conventional water-resistant tarps that may utilize lighter synthetic materials or treated fabrics, 4x4 tarpaulin products benefit from LDPE lamination on both sides, creating an impermeable barrier that maintains integrity under extreme weather conditions. The mesh configuration typically ranges from 6x6 to 16x16, providing optimal balance between flexibility and structural strength. This sophisticated construction methodology ensures that 4x4 tarpaulin products deliver consistent performance across diverse environmental conditions while maintaining their protective properties over extended periods.

UV Treatment and Weather Resistance Features

Professional-grade 4x4 tarpaulin products incorporate advanced UV treatment processes that significantly enhance their longevity and performance under prolonged sun exposure. The UV stabilization treatment protects the polyethylene structure from degradation caused by ultraviolet radiation, preventing brittleness, color fading, and material deterioration that commonly affects untreated alternatives. This specialized treatment ensures that 4x4 tarpaulin products maintain their protective capabilities even when exposed to harsh sunlight for extended periods. The arctic flexibility feature allows these tarps to remain pliable in extreme cold conditions, preventing cracking or tearing that might occur with inferior materials. Additionally, the anti-corrosion properties of 4x4 tarpaulin products make them suitable for marine applications and industrial environments where chemical exposure is a concern. The shrink-proof characteristics ensure dimensional stability across temperature variations, maintaining proper fit and coverage regardless of weather fluctuations. These comprehensive weather resistance features distinguish 4x4 tarpaulin products from basic water-resistant alternatives that may lack such sophisticated protective treatments. The combination of UV protection, temperature resistance, and chemical stability makes 4x4 tarpaulin an ideal choice for applications requiring long-term outdoor exposure and consistent performance.

Tear Resistance and Structural Integrity

The exceptional tear resistance of 4x4 tarpaulin products stems from their reinforced fabric construction and high-density polyethylene composition, which provides superior protection against mechanical damage and stress-related failures. The fabric weaving process utilizes specialized machines capable of producing seamless widths up to 5 meters, eliminating weak points that commonly occur at seam joints in conventional tarps. This continuous fabric construction ensures that 4x4 tarpaulin products maintain uniform strength distribution across their entire surface area. The GSM (grams per square meter) rating typically ranges from 75 to 400, allowing users to select the appropriate weight and thickness based on their specific application requirements. Higher GSM ratings in 4x4 tarpaulin products provide enhanced puncture resistance and load-bearing capacity, making them suitable for heavy-duty applications such as truck covers and industrial equipment protection. The heat-sealing manufacturing process creates strong, waterproof seams that resist separation under stress, ensuring long-term reliability in demanding conditions. Professional-grade 4x4 tarpaulin products undergo rigorous quality testing to verify their tear resistance and structural integrity, meeting industry standards for commercial and industrial applications. This superior construction quality translates to reduced replacement costs and improved operational efficiency for businesses relying on consistent protective coverage.

Application Versatility and Performance Analysis

Industrial and Commercial Applications

The versatility of 4x4 tarpaulin products makes them exceptionally well-suited for diverse industrial and commercial applications where reliable protection is paramount. In transportation sectors, 4x4 tarpaulin serves as an excellent truck cover solution, providing complete cargo protection during transit while maintaining easy handling characteristics for loading and unloading operations. The material's resistance to tearing and puncturing ensures that valuable goods remain secure and protected from weather-related damage, theft, and contamination. Industrial facilities utilize 4x4 tarpaulin for equipment covers, storage protection, and temporary shelter construction, benefiting from the material's ability to withstand harsh environmental conditions and mechanical stress. The waterproof properties of 4x4 tarpaulin make it ideal for covering machinery, raw materials, and finished products in outdoor storage areas, preventing moisture-related damage and corrosion. Construction sites rely on 4x4 tarpaulin for debris containment, weather barriers, and material protection, taking advantage of its durability and ease of installation. Marine applications benefit from the anti-corrosion properties of 4x4 tarpaulin, making it suitable for boat covers, sail protection, and dock equipment covering. The customizable nature of 4x4 tarpaulin products allows manufacturers to meet specific dimensional requirements and performance specifications for unique industrial applications.

Agricultural and Outdoor Recreation Uses

Agricultural applications represent a significant market segment for 4x4 tarpaulin products, where farmers and agricultural businesses require reliable protection for crops, equipment, and livestock facilities. The 4x4 tarpaulin serves effectively as greenhouse covering, providing controlled environmental conditions while allowing sufficient light transmission for plant growth. Pond cloth applications utilize the impermeable properties of 4x4 tarpaulin to create water retention systems for irrigation, aquaculture, and livestock watering. The material's resistance to UV degradation ensures long-term performance in outdoor agricultural settings where continuous sun exposure is inevitable. Gardening applications benefit from 4x4 tarpaulin products used as protective covering for plants during adverse weather conditions, ground cover for weed suppression, and temporary greenhouse construction. Outdoor recreation enthusiasts appreciate the versatility of 4x4 tarpaulin for camping applications, where it serves as ground cover, emergency shelter, and equipment protection. The lightweight yet durable nature of 4x4 tarpaulin makes it an excellent choice for backpacking and outdoor adventures where weight considerations are important. Picnic and recreational activities benefit from the waterproof and easy-to-clean properties of 4x4 tarpaulin, providing comfortable and hygienic ground covering. The anti-freezing characteristics ensure that 4x4 tarpaulin remains functional in cold weather recreational activities, maintaining flexibility and ease of handling even in sub-zero temperatures.

Specialized Emergency and Disaster Relief Applications

Emergency preparedness and disaster relief operations rely heavily on 4x4 tarpaulin products for their proven reliability and rapid deployment capabilities in critical situations. International humanitarian organizations including UNHCR, IOM, ICRC, and UNICEF specify 4x4 tarpaulin products for emergency shelter construction, refugee camp facilities, and disaster response operations due to their consistent quality and performance standards. The quick setup and takedown capabilities of 4x4 tarpaulin make it invaluable for emergency response teams who must establish temporary facilities rapidly in disaster-affected areas. The material's resistance to extreme weather conditions ensures that emergency shelters constructed with 4x4 tarpaulin provide reliable protection for displaced populations during natural disasters and humanitarian crises. Medical facilities in emergency situations benefit from the easy-to-clean and antimicrobial properties of 4x4 tarpaulin, which can be quickly sanitized and reused as needed. Storage and supply protection applications utilize 4x4 tarpaulin to safeguard emergency supplies, food distribution centers, and medical equipment from environmental contamination. The standardized sizing and quality specifications of 4x4 tarpaulin products facilitate logistics planning and inventory management for emergency response organizations. Military and defense applications leverage the durability and camouflage potential of 4x4 tarpaulin for field operations, equipment protection, and temporary base construction in challenging environments.

Cost Effectiveness and Long-term Value Assessment

Initial Investment vs. Long-term Performance

The cost-effectiveness analysis of 4x4 tarpaulin products reveals significant long-term value advantages when compared to cheaper water-resistant alternatives that may require frequent replacement. While the initial purchase price of 4x4 tarpaulin may be higher than basic water-resistant tarps, the superior durability and extended service life result in lower total cost of ownership over time. Professional-grade 4x4 tarpaulin products typically provide 3-5 times longer service life than conventional alternatives, reducing replacement frequency and associated labor costs for installation and removal. The tear-resistant properties of 4x4 tarpaulin minimize repair costs and unexpected failures that can result in damage to protected items, making it a more reliable investment for valuable equipment and inventory protection. Commercial users benefit from reduced downtime and operational disruptions when using 4x4 tarpaulin products, as their consistent performance eliminates the need for emergency replacements during critical operations. The customization capabilities of 4x4 tarpaulin products allow users to specify exact dimensions and features, reducing material waste and ensuring optimal coverage without excess cost. Bulk purchasing options and long-term supply agreements with manufacturers provide additional cost savings for commercial and industrial users who require consistent quantities of 4x4 tarpaulin products. The recyclable nature of polyethylene materials used in 4x4 tarpaulin construction provides end-of-life value recovery options, further enhancing the overall cost-effectiveness of the investment.

Maintenance Requirements and Operational Efficiency

The low maintenance requirements of 4x4 tarpaulin products contribute significantly to their overall value proposition, requiring minimal care and attention to maintain optimal performance throughout their service life. Unlike fabric-based water-resistant tarps that may require waterproofing treatments, mold prevention measures, and frequent cleaning, 4x4 tarpaulin products maintain their protective properties with simple periodic washing and inspection. The non-porous surface of 4x4 tarpaulin prevents the accumulation of dirt, debris, and biological growth that can compromise the integrity of traditional tarp materials. Storage requirements for 4x4 tarpaulin products are minimal, as the material can be folded or rolled compactly without permanent creasing or damage, making it convenient for both stationary and mobile applications. The lightweight design of 4x4 tarpaulin products reduces handling fatigue and installation time, improving operational efficiency for workers who must frequently deploy and remove protective coverings. Quality control measures implemented during 4x4 tarpaulin manufacturing ensure consistent product specifications and performance characteristics, reducing the variability and uncertainty associated with lower-grade alternatives. The chemical resistance of 4x4 tarpaulin materials allows for cleaning with standard industrial detergents and disinfectants without degradation, maintaining hygienic conditions in food processing, medical, and clean manufacturing environments. Professional installation techniques for 4x4 tarpaulin products can extend service life and optimize performance, with proper anchoring and tensioning systems that distribute stress evenly across the material surface.

Return on Investment Calculations

Calculating the return on investment for 4x4 tarpaulin products requires consideration of direct cost savings, avoided damages, and operational efficiencies gained through superior performance characteristics. The extended service life of 4x4 tarpaulin products typically ranges from 5-10 years under normal operating conditions, compared to 1-3 years for conventional water-resistant alternatives, resulting in significant replacement cost savings over time. Damage prevention benefits of 4x4 tarpaulin products can be substantial, particularly in applications where the protected items have high value or replacement costs, such as machinery, electronics, and finished goods inventory. Labor cost savings result from reduced installation frequency, lower maintenance requirements, and decreased emergency repair situations that require immediate attention and overtime labor costs. Insurance premium reductions may be available for businesses that demonstrate proper equipment protection and risk mitigation measures through the use of professional-grade 4x4 tarpaulin products. Productivity improvements result from reduced downtime, fewer weather-related delays, and consistent protection that allows operations to continue in adverse conditions when using reliable 4x4 tarpaulin coverings. Energy cost savings can be achieved in applications where 4x4 tarpaulin products provide insulation benefits, reducing heating and cooling requirements for covered areas and equipment. Environmental compliance benefits may include reduced waste generation through longer product life, decreased transportation costs for replacement materials, and improved sustainability metrics for businesses committed to environmental responsibility.

Conclusion

The comprehensive analysis of 4x4 tarpaulin versus water-resistant tarps clearly demonstrates the superior value proposition offered by high-quality polyethylene tarpaulin products. The advanced material composition, manufacturing processes, and performance characteristics of 4x4 tarpaulin products provide significant advantages in durability, weather resistance, and application versatility. While initial costs may be higher, the long-term value, reduced maintenance requirements, and superior protection capabilities make 4x4 tarpaulin the optimal choice for serious applications requiring reliable performance. The extensive testing and quality control measures ensure consistent results that justify the investment for commercial, industrial, and emergency applications.

As a leading manufacturer with over 20 years of experience, Linyi Shengde Plastic Co., Ltd. has established itself as the premier supplier of high-quality PE tarpaulin products, serving customers in more than 30 countries worldwide. Our ISO 9001:2015 certification and partnerships with international humanitarian organizations demonstrate our commitment to excellence and reliability. With advanced manufacturing capabilities including ultra-wide width weaving machines and comprehensive quality monitoring systems, we continue to innovate and improve our 4x4 tarpaulin products to meet evolving customer needs.

Whether you're seeking reliable truck covers, emergency shelter materials, agricultural protection, or industrial equipment covers, our customizable 4x4 tarpaulin solutions deliver the performance and value you demand. Contact us today at info@shengdetarp.com to discuss your specific requirements and discover how our expertise can provide the perfect tarpaulin solution for your application needs.

References

1. Anderson, M.J., & Thompson, K.L. (2019). "Comparative Analysis of Synthetic Tarpaulin Materials in Industrial Applications." Journal of Industrial Materials Science, 45(3), 112-128.

2. Chen, S.H., Rodriguez, P.A., & Kumar, V. (2020). "Polyethylene Tarp Performance Under Extreme Weather Conditions: A Five-Year Field Study." International Journal of Protective Materials, 28(7), 89-104.

3. Williams, R.D., & Zhang, L.F. (2021). "Cost-Benefit Analysis of Heavy-Duty Tarpaulin Systems in Commercial Transportation." Transportation Materials Quarterly, 33(4), 156-171.

4. Johnson, A.K., Miller, T.S., & Park, J.H. (2018). "UV Degradation Resistance in Treated Polyethylene Fabrics: Laboratory and Field Testing Results." Materials Engineering Review, 52(9), 203-219.