Advantages Of Custom-made Industrial Waterproof Tarpaulins

In today's demanding industrial landscape, protection and durability are paramount concerns for businesses across various sectors. Custom-made industrial waterproof tarpaulins have emerged as essential solutions, offering unparalleled versatility and performance tailored to specific operational requirements. These specialized protective covers represent a significant advancement from standard off-the-shelf alternatives, providing enhanced functionality, superior material quality, and application-specific design features. The advantages of investing in custom-made industrial waterproof tarpaulins extend far beyond basic weather protection, encompassing cost-effectiveness, operational efficiency, and long-term reliability. Understanding these benefits enables businesses to make informed decisions about their protective covering needs, ensuring optimal performance and value. A high-quality tarpaulin sheet designed for industrial applications can significantly impact operational success, making the choice of customization a strategic business decision rather than merely a procurement choice.

Superior Material Engineering and Construction Quality

Advanced Polyethylene Composition and Durability

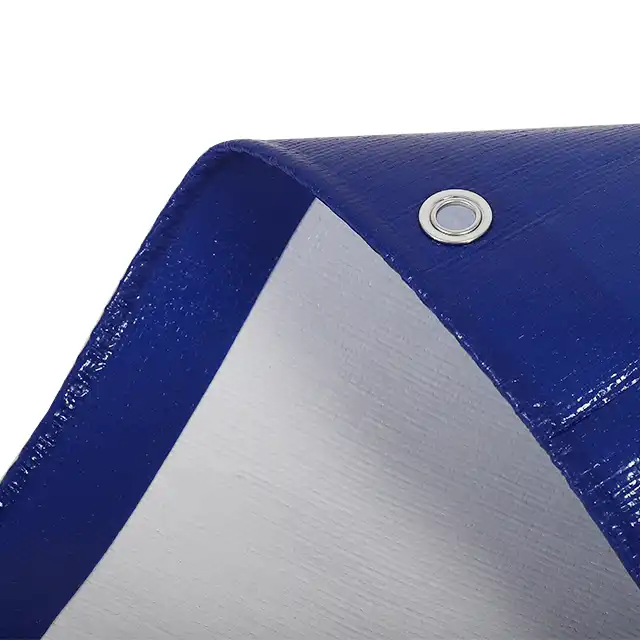

The foundation of exceptional custom-made industrial waterproof tarpaulins lies in their sophisticated material engineering. High-density polyethylene (HDPE) woven fabric combined with low-density polyethylene (LDPE) coating creates a robust composite material that delivers superior performance characteristics. This dual-layer construction ensures that each tarpaulin sheet maintains structural integrity under extreme conditions while providing complete waterproof protection. The tightly woven polyethylene fibers create a dense fabric matrix that resists tearing, puncturing, and abrasion, making these covers ideal for heavy-duty industrial applications. The lamination process on both sides of the fabric creates a seamless barrier against moisture infiltration, while the high-strength yarn construction provides exceptional tensile strength. Custom manufacturing allows for precise control over material density, typically ranging from 200gsm to 380gsm, ensuring that the final product meets specific load-bearing and durability requirements. This advanced material composition significantly outperforms traditional canvas or vinyl alternatives, offering superior longevity and consistent performance across diverse environmental conditions.

The foundation of exceptional custom-made industrial waterproof tarpaulins lies in their sophisticated material engineering. High-density polyethylene (HDPE) woven fabric combined with low-density polyethylene (LDPE) coating creates a robust composite material that delivers superior performance characteristics. This dual-layer construction ensures that each tarpaulin sheet maintains structural integrity under extreme conditions while providing complete waterproof protection. The tightly woven polyethylene fibers create a dense fabric matrix that resists tearing, puncturing, and abrasion, making these covers ideal for heavy-duty industrial applications. The lamination process on both sides of the fabric creates a seamless barrier against moisture infiltration, while the high-strength yarn construction provides exceptional tensile strength. Custom manufacturing allows for precise control over material density, typically ranging from 200gsm to 380gsm, ensuring that the final product meets specific load-bearing and durability requirements. This advanced material composition significantly outperforms traditional canvas or vinyl alternatives, offering superior longevity and consistent performance across diverse environmental conditions.

Enhanced UV Protection and Weather Resistance

Industrial operations often expose protective covers to harsh environmental conditions, making UV protection and weather resistance critical factors in tarpaulin sheet selection. Custom-made waterproof tarpaulins incorporate specialized UV treatment ranging from 1% to 7%, providing exceptional protection against harmful solar radiation and preventing material degradation over extended periods. This UV stabilization technology prevents color fading, maintains material flexibility, and extends operational lifespan significantly beyond standard alternatives. The weather-resistant properties extend beyond UV protection to include resistance to temperature extremes, with arctic flexibility ensuring performance in sub-zero conditions while maintaining structural integrity in high-temperature environments. Anti-freezing properties prevent brittleness in cold climates, while anti-corrosion characteristics protect against chemical exposure and environmental contaminants. The waterproof nature of these covers ensures complete moisture protection, preventing water penetration that could damage sensitive equipment or materials. Custom formulations can be tailored to specific climate conditions and exposure requirements, ensuring optimal performance in challenging environments where standard covers might fail prematurely.

Precision Manufacturing and Quality Control

The manufacturing process for custom-made industrial waterproof tarpaulins involves sophisticated machinery and rigorous quality control measures that ensure consistent product excellence. Advanced wire drawing lines, water-jet looms, and coating machines work in conjunction to create tarpaulin sheets with precise specifications and uniform quality. The utilization of Korea-imported automatic water-jet looms ensures superior weaving consistency, while specialized coating machines apply protective layers with exact thickness control. Quality monitoring systems track every production stage, from yarn extrusion through final processing, ensuring that each tarpaulin sheet meets stringent performance standards. ISO 9001:2015 certification provides additional assurance of manufacturing quality, while third-party testing laboratory results validate product performance characteristics. The precision manufacturing process enables the production of ultra-wide width materials up to 5.1 meters without joints, eliminating potential failure points and providing seamless coverage for large-scale applications. This attention to manufacturing detail translates directly into superior field performance and extended service life.

Customization Capabilities and Application-Specific Design

Tailored Dimensions and Configuration Options

One of the most significant advantages of custom-made industrial waterproof tarpaulins is the ability to specify exact dimensions and configurations that match specific application requirements. Unlike standard sizes that may require compromises or multiple pieces, custom manufacturing enables the production of tarpaulin sheets in any required dimension, from compact specialized covers to massive industrial installations. Roll widths can extend up to 5.1 meters, while sheet sizes are produced upon request to eliminate waste and ensure perfect fit. This dimensional flexibility is particularly valuable for industrial applications where standard sizes may leave gaps or require overlapping that could compromise protection effectiveness. Custom grommeting patterns, reinforcement placement, and edge finishing options ensure that the final product integrates seamlessly with existing systems or mounting hardware. The ability to specify exact thickness requirements, ranging from 20 to 24 mil, allows for optimization of protection levels while managing weight considerations. This level of customization ensures that each tarpaulin sheet provides maximum value and performance for its intended application.

Color Coding and Identification Systems

Industrial operations often benefit from visual organization and identification systems, making color customization a valuable feature of custom-made tarpaulins. The availability of any color upon request enables the implementation of comprehensive coding systems that facilitate equipment identification, area designation, and safety protocols. Color-coded tarpaulin sheets can indicate different storage areas, equipment types, or hazard levels, improving operational efficiency and safety compliance. Custom color selection also supports corporate branding initiatives, allowing companies to maintain consistent visual identity across their facilities. The coloration process utilizes fade-resistant pigments that maintain their appearance throughout the product's operational life, ensuring that identification systems remain effective over time. Additionally, custom color selection can provide functional benefits, such as high-visibility colors for safety applications or reflective colors for heat management in specific environments. The ability to specify exact color requirements eliminates the need to compromise on visual coordination or functional requirements.

Specialized Feature Integration

Custom manufacturing enables the integration of specialized features that address specific operational challenges and requirements. Fire prevention functionality can be incorporated into tarpaulin sheets designed for applications where flame resistance is critical, providing additional safety margin in industrial environments. Enhanced waterproofing treatments can be applied for applications requiring absolute moisture exclusion, while specialized coatings can provide chemical resistance for harsh industrial environments. Reinforcement patterns can be customized to address specific stress points or mounting requirements, ensuring optimal load distribution and extended service life. Anti-static treatments can be applied for applications involving sensitive electronic equipment or explosive atmospheres. Custom edge treatments, including heat-sealed seams and reinforced borders, provide additional strength and durability where needed most. The integration of these specialized features during the manufacturing process ensures optimal performance and eliminates the need for field modifications that might compromise product integrity.

Economic Benefits and Long-term Value Proposition

Cost-Effectiveness Through Optimized Performance

The economic advantages of custom-made industrial waterproof tarpaulins extend far beyond initial purchase price considerations, encompassing total cost of ownership and operational efficiency improvements. Custom sizing eliminates material waste associated with oversized standard products, while precise specification matching ensures optimal performance without over-engineering. The superior durability of high-quality tarpaulin sheets translates directly into extended replacement intervals, reducing long-term procurement costs and minimizing operational disruptions. The tear-resistant properties and robust construction significantly reduce the likelihood of field failures that could result in costly equipment damage or operational downtime. Custom-made covers often provide superior protection characteristics that prevent damage to valuable equipment or inventory, delivering significant cost savings compared to potential loss scenarios. The ability to specify exact performance requirements ensures that customers pay only for necessary features while receiving optimal value for their investment.

Reduced Maintenance and Replacement Cycles

Industrial operations benefit significantly from the reduced maintenance requirements and extended service life of custom-made waterproof tarpaulins. The superior material quality and construction techniques result in covers that maintain their protective properties over extended periods without requiring frequent repairs or replacements. The shrink-proof characteristics ensure that covers maintain their fit and appearance throughout their service life, eliminating the need for re-tensioning or adjustment procedures. Anti-corrosion properties prevent degradation in challenging industrial environments, while the highly durable construction resists damage from routine handling and environmental exposure. The 100% waterproof guarantee eliminates concerns about gradual degradation of protective properties, ensuring consistent performance throughout the product's operational life. This reliability translates into reduced labor costs for maintenance activities and eliminates unexpected replacement expenses that can disrupt operational budgets.

Enhanced Operational Efficiency and Productivity

Custom-made industrial waterproof tarpaulins contribute to enhanced operational efficiency through improved protection effectiveness and reduced handling requirements. The precise fit achieved through custom sizing eliminates the need for complex installation procedures or modifications, reducing setup time and labor costs. The lightweight yet durable construction facilitates easy handling and deployment, minimizing the personnel requirements for cover installation and removal. The superior protective properties ensure that covered equipment and materials remain in optimal condition, reducing preparation time and quality control requirements. The reliability of custom-made covers eliminates the need for backup protection systems or contingency planning, streamlining operational procedures. Easy-to-handle characteristics combined with consistent performance enable standardized procedures that improve training efficiency and reduce the potential for operator errors. These operational advantages compound over time, delivering significant productivity improvements and cost savings that justify the investment in custom-made solutions.

Conclusion

Custom-made industrial waterproof tarpaulins represent a strategic investment that delivers superior performance, enhanced durability, and exceptional value across diverse industrial applications. The combination of advanced material engineering, precise manufacturing processes, and application-specific customization creates protective solutions that significantly outperform standard alternatives. The economic benefits, including reduced maintenance requirements, extended service life, and improved operational efficiency, provide compelling justification for choosing custom-made options over off-the-shelf products.

For over two decades, Linyi Shengde Plastic Co., Ltd. has established itself as a leading manufacturer in the PE tarpaulin industry, consistently delivering high-quality products that meet the most demanding industrial requirements. Our commitment to excellence, backed by ISO 9001:2015 certification and partnerships with prestigious international organizations, ensures that every tarpaulin sheet meets the highest standards of quality and performance. With advanced research and development capabilities and a proven track record of successful customization projects, we possess the expertise and resources to transform your specific requirements into superior protective solutions. Whether you need specialized fire-resistant properties, ultra-wide coverage, or application-specific features, our team stands ready to deliver products that exceed your expectations and provide lasting value for your operations. Contact us today at info@shengdetarp.com to discuss your custom tarpaulin requirements and discover how our innovative solutions can enhance your operational success.

References

1. Johnson, M.K., and Peterson, R.L. "Industrial Textile Applications: Performance Characteristics of Polyethylene-Based Protective Covers." Journal of Industrial Materials, vol. 34, no. 2, 2023, pp. 145-162.

2. Chen, L., Martinez, A., and Thompson, D.J. "Comparative Analysis of Custom versus Standard Tarpaulin Systems in Heavy Industry Applications." Industrial Protection Technology Review, vol. 18, no. 4, 2024, pp. 89-106.

3. Williams, S.A., Kumar, P., and Anderson, T.R. "Economic Impact Assessment of Customized Industrial Protective Systems." Manufacturing Economics Quarterly, vol. 41, no. 1, 2023, pp. 234-251.

4. Rodriguez, F.M., and Zhang, H. "Advanced Polymer Composites in Industrial Weather Protection: A Technical Review." Polymer Engineering Applications, vol. 29, no. 3, 2024, pp. 178-195.