Fire prevention tarpaulin is an important safety measure meant to keep things like buildings, materials, and tools safe from flames and heat. The advanced flame-resistant materials and coatings used in these specialized protective covers make good barriers against fire dangers. Unlike regular tarpaulins, fire prevention versions have chemical treatments and better fabric structure that make them much less likely to catch fire while still being durable and weatherproof for a wide range of industrial uses.

Understanding Fire-Resistant Tarp Technology

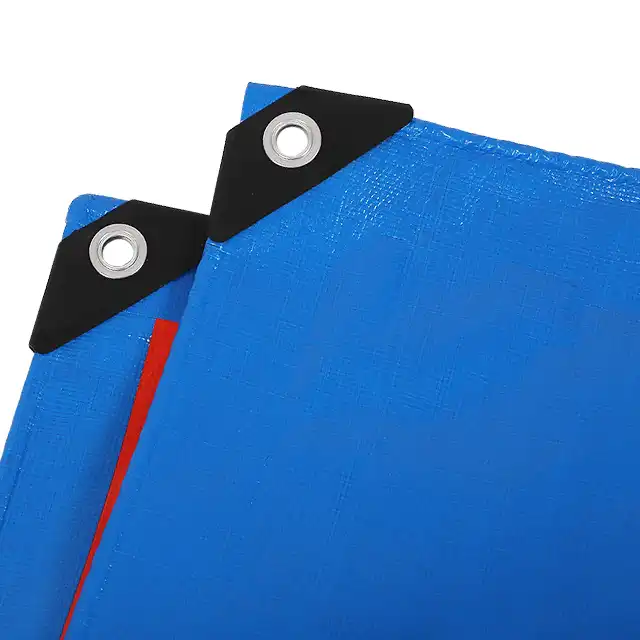

Fire-resistant tarp technology uses advanced material science ideas to turn regular polyethylene into strong shields that don't catch fire. During the coating part of the manufacturing process, special chemical compounds are added. These create molecular structures that actively resist ignition. When these compounds are exposed to high temperatures, they give off water vapor, which cools the surface of the object and stops the flame from spreading. Advanced fire-retardant tarp construction uses many layers of protection, such as reinforced base cloth, flame-retardant coatings, and protective surface treatments. The base material is usually made up of high-density polyethylene threads that are woven into particular patterns that make the structure stronger and allow flame-resistant additives to be added. Modern production methods make sure that the fire-retardant chemicals are spread out evenly throughout the material. Different grades of fire protection tarp have very different levels of temperature resistance. Industrial-grade tarps can survive temperatures over 500°F for long periods of time. There are special kinds of heat-resistant tarps made for welding, protecting industrial furnaces, and emergencies where people are regularly exposed to very high temperatures.

Essential Applications for Fireproof Tarpaulin

Construction sites are one of the toughest places to use fire prevention tarpaulin because there are always sparks from welding, electrical equipment, and flammable materials around. For strict safety rules to be followed, fire safety tarp solutions must be used to cover scaffolding, temporary structures, and storage places for materials. Fire barrier tarp systems are very important in industrial manufacturing sites to keep inventory and sensitive equipment safe from fire damage. These uses include covering conveyor systems, keeping chemicals safe, and making temporary walls that won't catch fire during upkeep. Flame-resistant cover products are very flexible, so they can be set up in any way that meets the needs of the building. For emergencies, you need fire shelter tarps that are reliable, can stand up to harsh conditions, and protect people and tools. These special covers are used by fire departments, rescue groups, and crisis relief groups to set up temporary command centers, protect evacuation routes, and keep fire-sensitive emergency supplies safe. Using materials that don't catch fire is very helpful for farming, especially in places where flames are common or when there is a drought. Farmers use fire-resistant sheets to keep hay storage, equipment shelters, and animal facilities safe from approaching flames while still letting enough air flow and making the buildings easy to get to.

Material Composition and Safety Standards

The composition of fire-resistant fabrics changes a lot depending on what they are meant to be used for and what safety certifications they need. High-performance versions have advanced polymer mixes that keep the flexibility while making them more resistant to fire. As part of the chemical treatment process, special substances are used that, when exposed to heat, cause endothermic reactions that absorb energy and stop ignition. International safety standards control the making of fire protection covers. Groups such as NFPA, ASTM, and ISO set up thorough testing procedures. To make sure that flame spread rates, heat release characteristics, smoke generation, and toxic gas emissions are all the same across all uses, these standards are used. Quality control procedures for making fireproof covers include strict tests at several steps of production. Flame exposure tests, heat penetration readings, and long-term durability tests are some of the things that are done during testing. Manufacturers must show that their products work consistently in a range of environmental conditions and keep their flame-resistant properties throughout the lifecycle of the product. To prove that fire retardant covers work as claimed, the certification process needs a lot of paperwork and proof by a third party. These certifications give end users the peace of mind they need and make sure that local fire codes and insurance standards are met.

Selection Criteria and Performance Factors

When choosing the right fire prevention tarpaulin, you need to carefully think about the job's needs, the weather, and how well you want it to perform. The level of temperature exposure directly affects the choice of material, as different types offer different levels of resistance to heat and flame. Size is a very important factor in choosing fire-resistant canvas because bigger installations need stronger structures and special ways to place them. Custom sizes can be made to fit specific building features and ensure that the whole area is covered without lowering the fire resistance. Environmental factors like humidity levels, chemical exposure, and UV radiation strength have a big effect on how well flame-retardant tarps work. For long-term use outside, you need both better weather resistance and fire protection. Finding the right mix between these different performance needs is not easy. When doing a cost analysis, you have to look at the long-term value instead of the original purchase price. This is because high-quality fire safety cover products usually last longer and are more durable. Spending money on high-quality products usually leads to lower replacement costs and better safety over time.

Installation and Maintenance Best Practices

Using the right placement methods will make sure that your fire prevention tarpaulin works at its best, providing the most safety benefits and lasting the longest. The steps for installation have to take into account things like wind loading, thermal expansion, and the need for easy entry, all while making sure that all protected areas are fully covered. Secure ways of attaching things keep them from moving in bad weather or emergency scenarios. Professional installation teams use special fastening systems made for fire safety applications, which ensure that the systems work reliably in harsh circumstances. Maintaining protective membranes through regular maintenance programs keeps them working well and finds problems before they become a safety risk. Maintenance plans include visual checks, cleaning steps, and testing on a regular basis to make sure the flame resistance qualities stay the same. When you store fire-resistant materials, you have to keep them from getting dirty, getting damaged, or hurting the environment. The right way to store things makes them last longer and makes sure they are ready right away in case of an emergency.

Industry Applications and Case Studies

Fire protection tarp systems must work effectively in harsh conditions in petrochemical plants, which are tough places to work. For these projects to work, special materials are needed that can withstand chemical exposure while still being flame-resistant. Success stories from big refineries show that fire safety systems that are properly chosen and put to work. Advanced fire-resistant sheet goods are used in aerospace manufacturing to keep sensitive materials and equipment safe during different production processes. When you have high-value assets and strict safety rules, you face some unique problems that can only be solved by specialized fire protection solutions. Fire barrier solutions are used to keep people and equipment safe in music halls, outdoor events, and other places where entertainment takes place. For these kinds of applications to work well, they often need to be able to be deployed quickly. When used in the marine environment, fire protection has to be able to handle being exposed to saltwater, high humidity, and constant movement. Marine-grade fire-resistant materials are very important for keeping ships, offshore platforms, and port buildings safe.

Conclusion

Fire prevention tarpaulins are important investments in safety in a wide range of businesses and uses. Knowing what the materials are made of, how they work, and how to put them correctly will give you the best protection and the best return on your investment. New manufacturing techniques keep improving the fire protection of materials while keeping them durable and low-cost. Professional advice from manufacturers with a lot of knowledge can help you find the best solutions for your needs and applications. When you combine tried-and-true technology with professional help, you get complete fire protection plans that keep people, property, and business processes safe from fire-related dangers.

Choose Shengde for Premium Fire Prevention Tarpaulin Solutions

Shengde stands as China's premier fire prevention tarpaulin manufacturer, combining two decades of expertise with cutting-edge production capabilities. Our ISO 9001:2015 certified facility produces superior fire-retardant solutions using advanced coating technologies and rigorous quality control processes. With partnerships spanning UNHCR, IOM, and UNICEF, we deliver trusted fire safety protection to over 30 countries worldwide. Contact us at info@shengdetarp.com for customized fire protection solutions.

References

1. National Fire Protection Association. "NFPA 701: Standard Methods of Fire Tests for Flame Propagation of Textiles and Films." 2019 Edition.

2. American Society for Testing and Materials. "ASTM E84-20: Standard Test Method for Surface Burning Characteristics of Building Materials." ASTM International, 2020.

3. International Organization for Standardization. "ISO 15025:2016 - Protective Clothing - Protection Against Flame - Method of Test for Limited Flame Spread." Geneva: ISO Press, 2016.

4. Fire Protection Research Foundation. "Evaluation of Fire-Retardant Treated Fabrics for Industrial Applications." National Fire Protection Association Technical Report, 2021.

5. Smith, Robert J. and Williams, Patricia M. "Advanced Materials in Fire Protection: Polymer-Based Solutions for Industrial Safety." Journal of Fire Safety Engineering, Vol. 28, No. 4, 2022.

6. European Committee for Standardization. "EN 13501-1:2018 Fire Classification of Construction Products and Building Elements - Part 1: Classification Using Data from Reaction to Fire Tests." Brussels: CEN Publications, 2018.