How to Choose the Right Tarpaulin for Cargo Protection?

Picture this scenario: your valuable cargo arrives at its destination damaged by rain, wind, or UV exposure simply because you chose the wrong protective covering. Every year, businesses lose millions due to inadequate cargo tarpaulin selection, leading to damaged goods, insurance claims, and lost customer trust. Selecting the right cargo tarpaulin is not just about finding any cover - it's about understanding specific protection requirements, material properties, and environmental challenges that could compromise your shipment's integrity during transport.

Understanding Cargo Tarpaulin Materials and Construction

When selecting a cargo tarpaulin for transportation needs, the material composition forms the foundation of effective protection. Modern cargo tarpaulin systems utilize various materials, each offering distinct advantages for specific applications. Polyethylene (PE) cargo tarpaulins represent the most popular choice due to their excellent balance of durability, cost-effectiveness, and weather resistance. These tarps feature high-density, tightly woven polyethylene fibers that create a robust barrier against moisture, dust, and environmental contaminants. The construction process involves weaving polyethylene threads into fabric, which is then laminated on both sides to enhance waterproof properties. Premium cargo tarpaulin products incorporate high-strength yarn that provides enhanced UV protection, preventing harmful sunrays from degrading both the tarp material and the covered cargo. The lamination process creates a completely waterproof barrier while maintaining flexibility and tear resistance essential for cargo transportation applications. Canvas and vinyl cargo tarpaulins offer alternative solutions for specialized applications. Canvas provides superior breathability and wind resistance, making it ideal for cargo that requires air circulation during transport. However, canvas requires additional waterproofing treatments for complete moisture protection. Vinyl cargo tarpaulins excel in industrial environments where chemical resistance and easy cleaning are priorities, though they typically carry higher costs than PE alternatives.

-

Weight Classifications and Performance Standards

Cargo tarpaulin selection must consider weight classifications that directly impact performance and application suitability. Light-duty cargo tarpaulins (65-100 GSM) work effectively for temporary coverage and indoor storage applications. These lightweight options provide basic protection while offering easy handling and reduced transportation costs. Medium-duty cargo tarpaulins (100-180 GSM) represent the optimal choice for most transportation applications. These products balance durability with practicality, offering excellent protection for truck covers, goods protection, and general cargo applications. The weight range provides sufficient strength to withstand transportation stresses while remaining manageable for regular use. Heavy-duty cargo tarpaulins (180-280 GSM) deliver maximum protection for demanding applications. These premium products feature enhanced tear resistance, superior UV protection, and extended service life. Heavy-duty cargo tarpaulins justify their higher cost through reduced replacement frequency and superior cargo protection in harsh environmental conditions.

Cargo Tarpaulin Size and Configuration Requirements

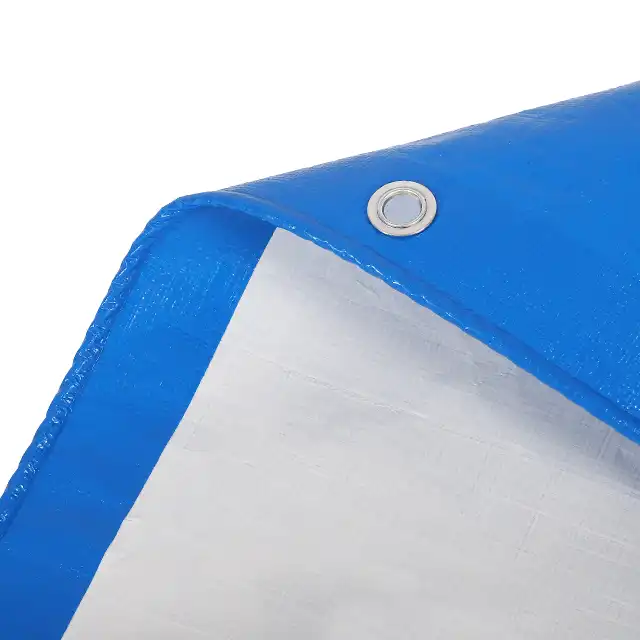

Proper sizing represents a critical factor in cargo tarpaulin effectiveness. Undersized covers leave cargo exposed to environmental hazards, while oversized tarps create handling difficulties and potential safety hazards during transport. Accurate measurement of cargo dimensions, including length, width, and height, ensures optimal coverage and protection. Modern cargo tarpaulin manufacturers offer flexible sizing options, with roll widths reaching up to 5.1 meters and custom sheet sizes available upon request. This flexibility accommodates various cargo configurations and transportation requirements. When calculating size requirements, consider cargo shape variations, securing mechanisms, and potential load shifting during transport. The configuration must also account for securing points and edge reinforcement. Quality cargo tarpaulins feature reinforced hems that add strength to stress points where securing mechanisms attach. Rust-resistant grommets, preferably made from brass or galvanized steel, provide reliable attachment points that withstand repeated use and harsh weather conditions without failure.

-

Color Selection and Visibility Considerations

Color selection in cargo tarpaulin applications serves both practical and safety purposes. Bright colors like orange enhance visibility during transport, improving safety for both drivers and other road users. Dark colors such as black or green provide better UV stability and hide stains more effectively, extending the apparent service life of the covering. Professional cargo operations often specify colors that align with company branding or regulatory requirements. Some transportation corridors require specific visibility standards that influence color selection. Additionally, light-colored cargo tarpaulins reflect heat more effectively, potentially reducing cargo temperature in sensitive applications. The mesh count specification affects both appearance and performance. Standard cargo tarpaulins feature mesh counts ranging from 10x10 to 14x14, with higher numbers indicating tighter weaves that provide superior protection but may reduce flexibility. The optimal mesh count balances protection requirements with handling characteristics for specific applications.

Cargo Tarpaulin Features and Special Applications

Advanced cargo tarpaulin products incorporate specialized features that enhance performance in specific applications. UV treatment levels ranging from 1% to 7% provide customized protection against solar degradation. Higher UV treatment percentages extend service life in applications involving prolonged sun exposure, such as outdoor storage or long-distance transportation. Waterproofing represents a fundamental requirement for most cargo tarpaulin applications. Modern products achieve 100% waterproof performance through advanced coating processes that create seamless barriers against moisture penetration. The coating thickness, typically ranging from 7 to 12 mils, determines both waterproof effectiveness and overall durability. Specialized applications require additional features such as fire prevention capabilities, enhanced tear resistance, and chemical compatibility. Fire-retardant cargo tarpaulins meet safety requirements for transporting combustible materials or operating in high-risk environments. Anti-corrosion treatments protect both the tarp and covered cargo from chemical damage in industrial applications.

-

Temperature Performance and Environmental Adaptability

Cargo tarpaulins must perform effectively across wide temperature ranges encountered during transportation. Premium products feature arctic flexibility that maintains pliability in sub-zero conditions, preventing cracking or brittleness that could compromise protection. This flexibility ensures reliable performance in cold climates while maintaining tear resistance and waterproof integrity. Anti-freezing properties prevent ice formation that could damage tarp materials or create handling difficulties. Shrink-proof construction maintains dimensional stability across temperature variations, ensuring consistent fit and protection throughout service life. These characteristics become particularly important for cargo operations spanning multiple climate zones or seasonal temperature variations. High-temperature performance requires consideration of thermal expansion, UV degradation, and material stability. Quality cargo tarpaulins maintain structural integrity and protective properties even when exposed to extreme heat during summer transportation or desert crossings. Heat-sealing capabilities in manufacturing ensure secure seam integrity that withstands thermal cycling without failure.

Quality Standards and Manufacturing Considerations

Professional cargo tarpaulin selection requires understanding of quality standards and manufacturing processes that ensure reliable performance. ISO 9001:2015 certification indicates manufacturers maintain comprehensive quality management systems throughout production processes. This certification provides confidence in consistent product quality and performance characteristics. Third-party testing laboratory reports verify claimed performance characteristics and provide objective quality assessments. Reputable cargo tarpaulin manufacturers provide detailed test reports covering waterproof performance, tear resistance, UV stability, and dimensional accuracy. These reports enable informed selection decisions based on verified performance data rather than marketing claims. Manufacturing capacity affects both product availability and customization capabilities. Large-scale manufacturers with monthly capacities exceeding 4000 metric tons can accommodate substantial orders while maintaining consistent quality and delivery schedules. Production line capabilities, including advanced heat-sealing equipment and quality control systems, directly impact final product quality and reliability.

-

OEM and Customization Options

Modern cargo operations increasingly require customized solutions that address specific application requirements. OEM and ODM services enable development of cargo tarpaulin products tailored to unique operational needs. Customization options include specialized sizes, enhanced performance characteristics, custom colors, and integrated branding elements. Professional manufacturers offer comprehensive customization services supported by experienced research and development teams. These teams possess the expertise to develop solutions for challenging applications such as ultra-wide coverage, specialized chemical resistance, or enhanced security features. Custom product development ensures optimal performance for specific cargo protection requirements. Quality customization services include prototype development, performance testing, and production scaling capabilities. This comprehensive approach ensures custom cargo tarpaulin solutions meet performance requirements while maintaining cost-effectiveness and reliable supply availability for ongoing operations.

Conclusion

Selecting the right cargo tarpaulin requires careful consideration of material properties, size requirements, environmental conditions, and quality standards. Proper selection protects valuable cargo while optimizing operational efficiency and cost-effectiveness. Understanding these factors enables informed decisions that ensure reliable protection throughout transportation and storage applications.

Cooperate with Linyi Shengde Plastic Co., Ltd.

As a leading China cargo tarpaulin manufacturer established in 2003, Linyi Shengde Plastic Co., Ltd. brings over 20 years of expertise to cargo protection solutions. Our state-of-the-art facility, spanning 60,000 square meters, houses advanced production equipment including 400+ Korea-imported water-jet looms, ultra-wide width braiding machines, and 7 high-capacity heat-sealing production lines capable of producing 100+ tons daily.

Our reputation as a trusted China cargo tarpaulin supplier stems from unwavering commitment to quality management. With ISO 9001:2015 certification and partnerships with international organizations including UNHCR, IOM, ICRC, and UNICEF, we demonstrate proven reliability in demanding applications. Our comprehensive quality monitoring systems ensure every cargo tarpaulin meets stringent performance standards verified by third-party testing laboratories.

As an innovative China cargo tarpaulin factory, our R&D team continuously develops advanced solutions including fire-prevention capabilities, enhanced waterproofing, and ultra-wide coverage options. We offer complete customization services for specialized requirements, supported by experienced technicians and flexible manufacturing capabilities. Whether you need standard solutions or custom designs, our cargo tarpaulin wholesale services provide competitive pricing without compromising quality.

Ready to secure High Quality cargo tarpaulin for your operations? Contact our expert team at info@shengdetarp.com for personalized solutions and competitive cargo tarpaulin price quotes. Discover why businesses across 30+ countries trust our cargo tarpaulin for sale solutions to protect their valuable cargo investments.

FAQ

Q: What weight classification should I choose for truck cargo transportation?

A: For most truck cargo applications, medium-duty tarpaulins (100-180 GSM) provide optimal protection and handling characteristics for regular transportation needs.

Q: How do I determine the correct size for my cargo tarpaulin?

A: Measure cargo length, width, and height, then add extra coverage for securing mechanisms and potential load shifting during transport.

Q: What's the difference between PE and PVC cargo tarpaulins?

A: PE tarpaulins offer excellent cost-effectiveness and weather resistance, while PVC provides superior chemical resistance and durability for industrial applications.

Q: How long can I expect a quality cargo tarpaulin to last?

A: With proper care, premium cargo tarpaulins typically provide 3-5 years of reliable service, depending on usage intensity and environmental conditions.

References

1. "Industrial Textiles and Tarpaulin Applications" - Johnson, M., Industrial Fabric Research Institute, 2024

2. "Transportation Cargo Protection Standards" - Smith, R., International Shipping Association, 2023

3. "Material Science in Protective Coverings" - Chen, L., Polymer Engineering Journal, 2024

4. "Quality Management in Textile Manufacturing" - Davis, K., Manufacturing Quality Standards Board, 2023