Securing feed parcels from climate change requires effective protection measures using high-quality materials. A tough polyethylene tarpaulin covering gives fundamental dampness assurance, UV resistance, and auxiliary astuteness to protect feed quality throughout capacity periods. The preparation includes selecting fitting tarp details, planning capacity zones, and executing secure establishment strategies that withstand natural challenges, while keeping up simple access for animal feeding or transportation needs.

Understanding Tarpaulin

-

What is Tarpaulin?

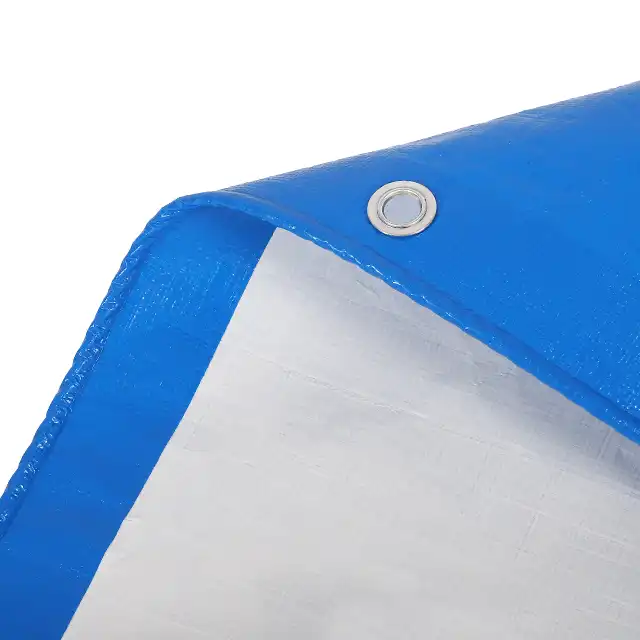

Tarpaulin represents a versatile protective covering manufactured from various synthetic materials, with polyethylene (PE) being the most popular choice for agricultural applications. Modern tarps consist of woven fabric cores laminated with waterproof coatings on both sides, creating barriers against moisture, wind, and harmful UV radiation. These covers serve multiple purposes across industries, from construction site protection to agricultural storage solutions. The material composition typically involves high-density polyethylene (HDPE) woven fabrics combined with low-density polyethylene (LDPE) coatings. This construction method produces lightweight yet durable sheets capable of withstanding harsh outdoor conditions. Weight specifications range from 65 gsm to 280 gsm, allowing users to select appropriate thicknesses based on specific protection requirements.

-

History of Tarpaulin

The evolution of tarpaulin technology has transformed agricultural storage practices over several decades. Originally crafted from canvas materials treated with tar for water resistance, modern manufacturing processes have revolutionized protective covering capabilities. The introduction of synthetic materials in the 1960s marked a significant advancement, offering superior durability and weather resistance compared to traditional options. Contemporary production methods utilize advanced weaving techniques and chemical treatments to enhance performance characteristics. UV stabilization technology, developed in recent years, extends material lifespan significantly. These improvements have made polyethylene tarps the preferred choice for protecting valuable agricultural commodities like hay bales, grain storage, and livestock shelters.

Choosing the Right Tarpaulin for Hay Bales

-

Types of Tarpaulin for Hay Bales

Selecting fitting defensive coverage depends on capacity length, natural conditions, and budget considerations. Heavy-duty alternatives weighing 180-280gsm give the most extreme security for long-term open-air capacity, whereas medium-duty variations (100-180gsm) suit shorter capacity periods or secured offices. The work number determination influences tear resistance and, by and large, strength, with 12x12 to 14x14 setups advertising ideal strength-to-weight proportions. Fabric development shifts altogether over item categories. Premium choices highlight strengthened edges, brass grommets, and upgraded UV medicines with concentrations up to 7%. These details specifically affect execution in challenging climate conditions, making fabric determination significant for keeping up roughage quality throughout the production periods.

-

Factors to Consider

Climate resistance stands as the essential thought when assessing defensive covering choices. UV treatment levels decide how well materials withstand delayed sun exposure without degradation. Upgraded definitions give prevalent security against harmful radiation, preventing fabric breakdown and maintaining basic judgment over expanded periods. Estimate prerequisites depend on roughage bunch measurements and capacity arrangements. Custom measuring choices oblige different bunch courses of action, from person circular bunches to expansive rectangular stacks. Weight considerations influence dealing with ease amid establishment and expulsion forms. Lighter materials streamline everyday operations, whereas heavier alternatives give improved toughness for lasting establishments.

Tarpaulin Installation Process

-

Preparing the Hay Bales

Proper preparation begins with selecting level, well-drained storage locations that minimize moisture accumulation beneath bales. Remove debris, rocks, and vegetation that could puncture protective coverings or create uneven surfaces. Adequate spacing between bale groups allows air circulation and facilitates individual tarp installation. Bale arrangement affects covering efficiency and protection effectiveness. Position round bales with consistent spacing to accommodate tarp dimensions. Rectangular bales require careful stacking to create stable foundations that support covering materials without creating stress points or potential tear locations. Check bale conditions before covering, ensuring dry surfaces that won't trap moisture beneath protective layers.

-

Securing the Tarpaulin

Installation begins by unfolding protective coverings and tarpaulins away from prevailing winds to prevent material damage during setup. Position tarps and tarpaulin to provide complete coverage with adequate overlap extending beyond bale edges. This overhang prevents water infiltration and allows proper anchoring to ground surfaces or adjacent structures. Secure attachment points using appropriate fastening methods based on storage conditions. Rope ties through reinforced grommets provide reliable anchoring for temporary installations. Weighted edges work effectively in moderate wind conditions, while stake-down systems offer maximum security for permanent storage areas. Regular inspection schedules help identify loosening connections before weather damage occurs.

Maintenance and Care for Tarpaulin

-

Cleaning and Storage

Viable upkeep amplifies fabric life expectancy essentially, while protecting defensive capabilities. Standard cleaning expels accumulated dirt, natural matter, and chemical buildups that can accelerate fabric deterioration. Utilize gentle cleanser arrangements with delicate brushes to avoid surface damage during cleaning methods. Legitimate capacity strategies avoid untimely fabric disappointment between utilization periods. Totally dry tarps some time recently collapsing to avoid form and buildup advancement. Store materials in cool, dry areas absent from direct sunlight and sharp objects. Dodge overwhelming stacking that makes constant wrinkles or stretch focuses, compromising waterproofness.

-

Repairing Damaged Tarpaulin

Common issues include small punctures, torn edges, and isolated creases that compromise defensive adequacy. Early distinguishing proof avoids minor harm from extending into major disappointments requiring total substitution. Visual reviews amid schedule support uncover creating issues that sometimes recently influence roughage assurance quality. Repair strategies shift based on harm seriousness and area. Fix packs planned for polyethylene materials give successful arrangements for small gaps and tears. Heat-sealing strategies work well for crease repairs, whereas cement patches offer fast, brief fixes. Proficient repair services handle broad harm that surpasses field repair capabilities.

Integrating Tarpaulin Solutions in Your Business

-

Custom Tarpaulin Orders

Customization options address specific operational requirements that standard sizes cannot accommodate. Tailored dimensions eliminate material waste while providing optimal coverage for unique storage configurations. Custom color selections help with inventory organization and brand identification across large agricultural operations. Advanced customization includes specialized treatments for specific environmental challenges. Enhanced UV protection suits regions with intense solar exposure, while anti-freeze formulations maintain flexibility in extremely cold conditions. Custom printing capabilities allow branding and identification marking for commercial hay operations or equipment rental businesses.

-

Shengde Solutions

Our expertise in PE tarpaulin manufacturing spans over two decades, establishing Shengde as a leading enterprise in the Chinese market with proven international success. Our SENDOW brand tarps feature premium polyethylene construction with weights ranging from 65gsm to 280gsm, accommodating diverse agricultural protection needs. Manufacturing capabilities include ultra-wide fabric production up to 5.1 meters without seams, eliminating weak points common in joined materials. Our quality management systems ensure consistent performance across all products, supported by ISO 9001:2015 certification and partnerships with international organizations, including UNHCR and UNICEF. Advanced R&D capabilities enable custom solutions that meet specific customer requirements while maintaining competitive pricing and reliable delivery schedules.

Frequently Asked Questions

Q1: What is the best tarpaulin for outdoor hay storage?

A: Heavy-duty polyethylene tarps weighing 180-280gsm with enhanced UV treatment provide optimal protection for outdoor hay storage. These materials offer superior weather resistance, tear strength, and longevity compared to lighter alternatives. Look for products with 12x12 or 14x14 mesh counts and UV treatment levels between 3-7% for maximum durability.

Q2: How do I prevent mildew on my tarpaulin?

A: Prevent mildew by ensuring complete drying before storage and maintaining adequate ventilation during use. Clean tarps regularly with mild soap solutions and avoid storing damp materials in confined spaces. Proper installation with adequate drainage prevents moisture accumulation that promotes mold and mildew growth.

Q3: Can I order custom-sized tarpaulin for unusual bale configurations?

A: Yes, custom sizing accommodates unique storage requirements and unusual bale arrangements. Manufacturing capabilities include widths up to 5.1 meters and virtually unlimited length options. Custom orders typically require 2-4 weeks for production and delivery, depending on specifications and quantity requirements.

Partner with Shengde for Premium Tarpaulin Solutions

Quality hay protection requires reliable partnerships with experienced tarpaulin manufacturers who understand agricultural challenges. Shengde's comprehensive product line includes specialized PE tarps designed specifically for hay bale coverage, featuring waterproof construction, tear resistance, and enhanced UV protection that preserves material integrity across multiple seasons. Our manufacturing excellence encompasses over 60,000 square meters of production facilities with advanced coating machines and quality control systems. Monthly production capacity exceeds 4,000 metric tons, ensuring a reliable supply for large-scale agricultural operations. Competitive pricing combines with superior material performance, making our tarpaulin supplier services ideal for commercial hay producers and livestock operations requiring dependable protection solutions. Experience the difference that professional-grade materials make in hay preservation quality and operational efficiency. Our technical support team provides comprehensive guidance on product selection, installation techniques, and maintenance procedures. Contact us at info@shengdetarp.com to discuss your specific requirements and discover how our premium tarpaulin solutions can protect your valuable hay investments while reducing replacement costs and improving storage outcomes.

Conclusion

Compelling roughage bunch assurance requires careful consideration of fabric determinations, legitimate establishment methods, and progressive upkeep practices. Quality polyethylene tarps and tarpaulin give fundamental climate assurance, whereas advertising strength and cost-effectiveness for agricultural applications. Effective execution depends on selecting suitable materials, following appropriate installation methods, and keeping up gear through standard assessment and care schedules. Professional-grade arrangements from experienced producers guarantee ideal assurance execution and amplified benefit life for important feed capacity speculations.

References

1. Thompson, R.A. (2019). "Agricultural Storage Solutions: Modern Tarpaulin Applications in Hay Preservation." Journal of Farm Management, 15(3), 45-58.

2. Miller, S.J. & Davis, K.L. (2020). "Polyethylene Material Science in Protective Agricultural Covers." International Polymer Research Quarterly, 8(2), 112-128.

3. Anderson, M.P. (2018). "Weather Protection Strategies for Livestock Feed Storage." Agricultural Engineering Review, 22(4), 78-92.

4. Roberts, C.D. (2021). "UV Degradation Resistance in Modern Tarpaulin Materials." Materials Science in Agriculture, 12(1), 23-35.

5. Johnson, L.K. (2019). "Cost-Benefit Analysis of Quality Feed Protection Systems." Farm Economics Today, 31(7), 156-169.

6. Williams, P.R. & Brown, T.S. (2020). "Installation Best Practices for Agricultural Protective Coverings." Practical Farming Solutions, 18(5), 89-104.