How to Use Tarpaulins to Protect Your Valuables?

Picture this: a sudden storm hits while your valuable equipment sits exposed, or harsh UV rays slowly degrade your precious belongings stored outdoors. The frustration of discovering weather-damaged property is all too common, but it's entirely preventable. A high-quality protective tarpaulin serves as your first line of defense against nature's unpredictable elements, offering reliable shield for vehicles, machinery, construction materials, and countless other valuables. Understanding how to properly select, position, and secure protective tarpaulin solutions can save thousands in replacement costs while ensuring your investments remain pristine regardless of weather conditions.

Essential Types of Protective Tarpaulin for Different Applications

-

Heavy-Duty Polyethylene Protective Tarpaulin

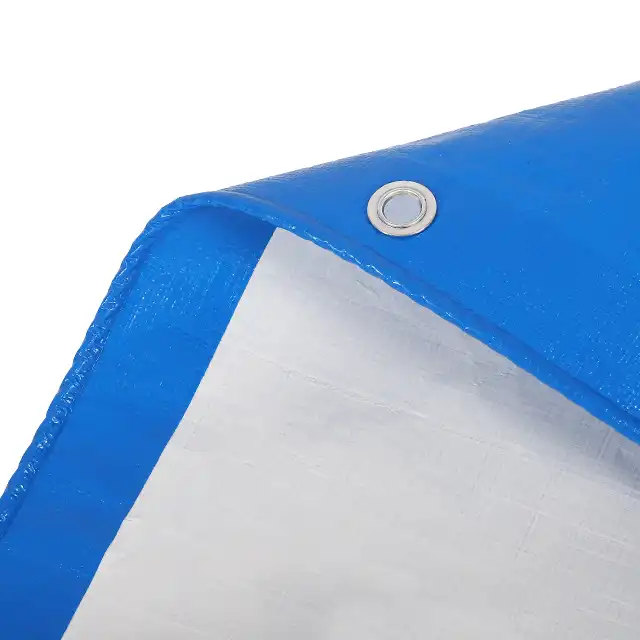

When protecting valuable assets, the material composition of your protective tarpaulin makes all the difference. Heavy-duty polyethylene tarpaulins represent the gold standard for comprehensive protection, constructed from high-density, tightly woven polyethylene fibers that undergo lamination on both sides for maximum durability. These protective tarpaulin solutions feature weights ranging from 100gsm to 280gsm, with mesh counts between 10x10 and 14x14, ensuring optimal strength-to-weight ratios. The advanced manufacturing process involves yarn extruding through high-tech machines, creating consistent thickness from 7 to 12 mil, while specialized UV treatment ranging from 1% to 7% provides exceptional protection against harmful solar radiation that can cause fading and material degradation.

-

Waterproof Protective Tarpaulin Features

The waterproofing capabilities of modern protective tarpaulin extend far beyond basic water resistance. Premium waterproof protective tarpaulin incorporates HDPE woven fabric combined with LDPE coating, creating an impermeable barrier that maintains integrity under extreme weather conditions. These advanced materials demonstrate remarkable tear resistance, anti-freezing properties, and arctic flexibility, making them suitable for year-round outdoor applications. The 100% waterproof guarantee ensures complete protection against moisture infiltration, while additional features like anti-corrosion and shrink-proof characteristics maintain dimensional stability even under prolonged exposure to harsh environmental conditions.

Strategic Placement Techniques for Maximum Protection

-

Vehicle and Equipment Coverage with Protective Tarpaulin

Protecting vehicles and heavy equipment requires strategic protective tarpaulin placement that accounts for air circulation, secure anchoring, and accessibility needs. Begin by selecting appropriately sized protective tarpaulin that provides adequate coverage while allowing for proper ventilation underneath. Position the protective tarpaulin to create gentle slopes that encourage water runoff rather than pooling, which can cause premature wear and potential leakage. For vehicles, ensure the protective tarpaulin extends beyond the vehicle footprint by at least two feet on all sides, providing comprehensive protection against driving rain and wind-blown debris. When covering construction equipment, focus on protecting critical mechanical components, hydraulic systems, and electrical connections that are most vulnerable to moisture damage.

-

Construction and Building Material Protection

Construction sites present unique challenges for protective tarpaulin deployment, requiring solutions that balance accessibility with comprehensive weather protection. Heavy-duty protective tarpaulin serves multiple functions in construction environments, from covering material stockpiles to protecting partially completed structures from weather damage. Strategic placement involves creating temporary weather barriers using properly tensioned protective tarpaulin systems that can withstand wind loads while maintaining structural integrity. For lumber protection, ensure adequate air circulation beneath the protective tarpaulin to prevent moisture accumulation that could lead to warping or mold development. When protecting concrete during curing processes, use protective tarpaulin to maintain optimal moisture levels while shielding against temperature extremes that could compromise structural integrity.

Professional Securing Methods for Protective Tarpaulin

-

Advanced Anchoring Systems

Professional protective tarpaulin installation requires sophisticated anchoring systems that distribute stress loads evenly across the entire covering surface. The most effective approach involves utilizing multiple attachment points with graduated tension levels, preventing stress concentration that could lead to tearing or failure. Begin with corner anchor points using heavy-duty grommets spaced no more than two feet apart, ensuring each grommet receives appropriate load distribution through reinforced webbing or rope systems. For larger installations, implement intermediate anchor points along the perimeter, creating a continuous support network that maintains protective tarpaulin stability under varying wind conditions.

-

Weather-Resistant Fastening Solutions

Selecting appropriate fastening hardware directly impacts the long-term effectiveness of your protective tarpaulin installation. Professional-grade installations utilize corrosion-resistant hardware including stainless steel grommets, galvanized turnbuckles, and weather-resistant rope materials that maintain strength characteristics under prolonged environmental exposure. Bungee cord systems provide dynamic tension adjustment capabilities, accommodating thermal expansion and contraction cycles that occur with temperature variations. For permanent installations, consider buried anchor systems that provide superior holding power while maintaining clean aesthetic appearances above ground level.

Specialized Applications of Protective Tarpaulin

-

Agricultural and Aquaculture Protection

Modern agricultural operations increasingly rely on protective tarpaulin solutions for crop protection, livestock shelter, and equipment storage applications. In aquaculture settings, impermeable protective tarpaulin serves as pond liners, preventing water loss while maintaining optimal water quality conditions for fish and aquatic plant cultivation. Greenhouse applications utilize specially formulated protective tarpaulin materials that provide weather protection while allowing controlled light transmission for optimal plant growth conditions. Orchard protection involves deploying lightweight yet durable protective tarpaulin systems that shield fruit trees from hail damage, excessive sun exposure, and pest infiltration during critical growing periods.

-

Industrial and Commercial Uses

Industrial facilities utilize protective tarpaulin for diverse applications ranging from temporary building enclosures to hazardous material containment systems. These specialized protective tarpaulin solutions must comply with specific industrial standards for chemical resistance, fire retardancy, and environmental safety. Commercial transportation operations depend on truck cover protective tarpaulin to secure cargo loads while providing weather protection during transit. The versatility of modern protective tarpaulin materials allows customization for specific industrial requirements, including special coatings, reinforced stress points, and integrated fastening systems designed for rapid deployment and removal.

Long-Term Maintenance and Care Strategies

-

Preserving Protective Tarpaulin Integrity

Proper maintenance extends the service life of protective tarpaulin while ensuring continued protection effectiveness. Regular inspection schedules should focus on identifying early signs of wear, including UV degradation, mechanical stress points, and potential puncture locations. Cleaning procedures involve gentle washing with mild detergents, avoiding harsh chemicals that could compromise the waterproof coatings or weaken fabric fibers. Storage practices significantly impact longevity, requiring dry, ventilated storage areas that prevent mold and mildew development while avoiding excessive folding that could create permanent creases or stress concentration points.

-

Performance Optimization Techniques

Maximizing protective tarpaulin performance involves understanding the relationship between environmental conditions, material properties, and installation techniques. Seasonal adjustments may be necessary to account for changing weather patterns, with particular attention to snow load considerations in winter climates and increased UV protection requirements during summer months. Professional installations benefit from periodic tension adjustments that compensate for material relaxation and thermal expansion cycles. Documentation of maintenance activities helps identify patterns that could indicate the need for replacement or upgrade to higher-performance protective tarpaulin materials.

Conclusion

Effective protective tarpaulin utilization requires understanding material properties, proper installation techniques, and ongoing maintenance requirements. By selecting appropriate protective tarpaulin solutions and implementing professional securing methods, valuable assets receive reliable protection against weather damage, UV degradation, and environmental contamination. The investment in quality protective tarpaulin pays dividends through reduced replacement costs and extended equipment life.

Cooperate with Linyi Shengde Plastic Co., Ltd.

As a leading China protective tarpaulin manufacturer established in 2003, Linyi Shengde Plastic Co., Ltd. offers comprehensive protective tarpaulin solutions backed by over two decades of industry expertise. Our state-of-the-art facility spans 60,000 square meters and employs over 1,000 skilled workers operating advanced production equipment including 400+ Korea-imported water-jet looms and 7 high-capacity production lines generating 100+ tons daily output. As a trusted China protective tarpaulin supplier, we maintain partnerships with prestigious international organizations including UNHCR, IOM, ICRC, and UNICEF, demonstrating our commitment to quality and reliability. Our China protective tarpaulin factory features ISO 9001:2015 certification and utilizes advanced quality monitoring systems throughout the production process. Whether you need China protective tarpaulin wholesale quantities or custom solutions, our research and development team delivers innovative protective tarpaulin products including ultra-wide width options up to 5 meters, fire-resistant formulations, and enhanced waterproof technologies. Contact our High Quality protective tarpaulin specialists at info@shengdetarp.com for competitive protective tarpaulin price quotes and personalized protective tarpaulin for sale solutions.

FAQ

Q: What weight protective tarpaulin is best for outdoor vehicle storage?

A: For vehicle protection, use heavy-duty protective tarpaulin weighing 180-280gsm with UV treatment and reinforced grommets for secure anchoring.

Q: How do I prevent wind damage to my protective tarpaulin installation?

A: Use multiple anchor points spaced 2 feet apart, create gentle slopes for wind flow, and employ dynamic tension systems with bungee cords.

Q: Can protective tarpaulin be used for permanent outdoor installations?

A: Yes, heavy-duty protective tarpaulin with UV treatment can provide long-term protection when properly installed and maintained with regular inspections.

Q: What's the difference between waterproof and water-resistant protective tarpaulin?

A: Waterproof protective tarpaulin provides complete moisture barrier protection, while water-resistant materials offer limited protection against light rain only.

References

1. "Protective Covering Materials for Construction and Industrial Applications" by Johnson, M.R. and Stevens, K.L., Industrial Materials Research Institute

2. "Weather Protection Systems: Design and Implementation Guide" by Thompson, A.D., Construction Technology Publishers

3. "Polyethylene Fabric Technologies in Protective Applications" by Chen, W.H. and Martinez, R.S., Advanced Materials Engineering Journal

4. "Environmental Protection Standards for Outdoor Storage Facilities" by Anderson, P.J., Environmental Safety Council Publications