PE Tarpaulin Covers for Lumber and Timber Transport

In the lumber and timber transportation industry, protecting valuable wood products from environmental damage during transit is crucial for maintaining quality and preventing financial losses. PE tarpaulin covers have emerged as the industry standard for safeguarding lumber and timber shipments against rain, UV radiation, dust, and other external factors that can compromise wood integrity. These specialized polyethylene covers offer superior waterproofing, tear resistance, and durability compared to traditional canvas or vinyl alternatives. With the increasing demand for sustainable forestry products and the need for efficient logistics solutions, PE tarpaulin covers provide an essential protective barrier that ensures timber arrives at its destination in pristine condition, making them indispensable for lumber yards, construction companies, and transportation firms worldwide.

Essential Features and Specifications of PE Tarpaulin for Timber Protection

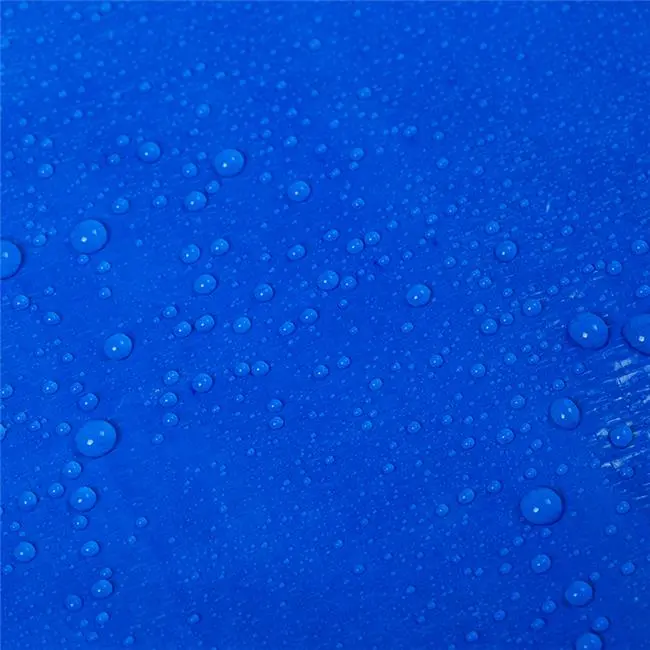

When selecting PE tarpaulin covers for lumber and timber transport, understanding the critical specifications and features ensures optimal protection for your valuable cargo. High-quality PE tarpaulin manufactured from premium polyethylene materials offers exceptional durability with mesh configurations ranging from 6x6 to 16x16, providing the perfect balance between strength and flexibility. The denier count, typically ranging from 600D to 1800D, directly correlates to the tarpaulin's tear resistance and longevity, making it essential for protecting heavy timber loads during long-distance transportation. Professional-grade PE tarpaulin features GSM ratings between 75-400gsm, with higher GSM ratings providing enhanced protection for premium lumber shipments. The surface treatment of PE tarpaulin plays a vital role in its protective capabilities, with LDPE lamination on both sides ensuring complete waterproof protection that prevents moisture penetration into timber grain structures. UV treatment is particularly crucial for lumber transport, as prolonged sun exposure can cause wood discoloration and structural weakening. Advanced PE tarpaulin covers incorporate anti-UV additives that maintain their protective properties even after extensive outdoor exposure, ensuring consistent protection throughout multiple transportation cycles. The customizable width options, ranging from narrow rolls to ultra-wide 40-meter configurations, allow for complete coverage of various lumber stack sizes and transportation vehicle dimensions. Temperature resistance is another critical feature of quality PE tarpaulin, with arctic flexibility ensuring the cover remains pliable and effective in extreme weather conditions. This anti-freezing capability prevents the tarpaulin from becoming brittle in cold climates, which is essential for timber transport routes through varying geographical conditions. The shrink-proof characteristics ensure dimensional stability, preventing the cover from distorting under temperature fluctuations and maintaining proper fit over lumber loads. These comprehensive specifications make PE tarpaulin an ideal solution for protecting timber investments during transportation, storage, and temporary outdoor exposure.

Comprehensive Protection Solutions for Different Timber Transport Scenarios

The versatility of PE tarpaulin covers makes them suitable for various timber transport scenarios, from short-distance local deliveries to international shipping operations. For truck-based timber transportation, custom-fitted PE tarpaulin covers provide complete protection while allowing for easy loading and unloading operations. The tear-resistant properties ensure the cover maintains its integrity even when subjected to the mechanical stresses of securing and unsecuring cargo, while the lightweight nature of polyethylene reduces additional weight burden on transportation vehicles. Professional drivers appreciate the easy-to-handle characteristics of PE tarpaulin, which significantly reduces the time and effort required for cargo protection procedures. Railway timber transport presents unique challenges that PE tarpaulin effectively addresses through its superior weather resistance and secure fastening capabilities. The 100% waterproof barrier prevents rain and snow infiltration that could lead to timber warping, staining, or fungal growth during extended rail journeys. The anti-corrosion properties of PE tarpaulin ensure the cover does not react with metal railcar surfaces, maintaining both the tarpaulin's integrity and the railcar's condition. For maritime timber shipping, PE tarpaulin covers provide essential protection against salt spray and oceanic moisture that can severely damage untreated lumber during sea transport. Specialized applications include temporary timber storage at construction sites, where PE tarpaulin serves as an effective weather shelter for lumber stockpiles awaiting use. The UV treatment prevents degradation of both the tarpaulin and the protected timber, making it suitable for extended outdoor storage periods. Lumber yards benefit from PE tarpaulin's durability for creating temporary covered storage areas, protecting inventory from seasonal weather variations while maintaining accessibility for customer selection and loading operations. The highly durable construction ensures these covers maintain their protective properties through repeated handling and repositioning, providing cost-effective long-term protection solutions for timber industry professionals.

Quality Manufacturing Standards and Advanced Production Capabilities

The manufacturing excellence behind premium PE tarpaulin covers relies on sophisticated production processes and rigorous quality control systems that ensure consistent performance across all applications. Linyi Shengde Plastic Co., Ltd exemplifies industry-leading manufacturing standards with advanced yarn extruding capabilities utilizing 30+ high-tech machines that produce yarn thickness ranging from 400D to 2500D. This precision in raw material production ensures the PE tarpaulin maintains uniform strength characteristics throughout its construction, providing reliable protection for valuable timber cargo. The fabric weaving process employs unique 5-meter and 4-meter width machines alongside 400+ Korea-imported automatic water-jet looms, enabling production of seamless PE tarpaulin covers up to 5 meters wide without joints that could compromise waterproof integrity. Quality management systems incorporating ISO 9001:2015 certification standards ensure every PE tarpaulin meets stringent performance criteria through comprehensive testing protocols. Advanced quality testing equipment monitors tensile strength, waterproof performance, UV resistance, and dimensional stability throughout the production process. The established quality monitoring system covers every production stage, from initial polyethylene processing through final product inspection, ensuring consistent quality that lumber transport professionals can depend on. Third-party testing laboratory results validate the superior performance characteristics of professionally manufactured PE tarpaulin, providing customers with confidence in their protective covering investment. The research and development capabilities driving PE tarpaulin innovation include breakthrough developments in ultra-wide width braiding technology, enabling production of specialized covers for oversized timber loads. Fire prevention function development has created PE tarpaulin options suitable for environments with heightened fire safety requirements, expanding application possibilities in industrial timber handling facilities. Strong waterproof function enhancement ensures complete moisture barrier protection, critical for preserving lumber quality during transport through varying climate conditions. These technological advances demonstrate the commitment to continuous improvement in PE tarpaulin performance, meeting evolving industry requirements for timber protection solutions that exceed traditional covering materials in every aspect of protective capability and operational convenience.

Conclusion

PE tarpaulin covers represent the optimal solution for lumber and timber transport protection, combining superior weather resistance, durability, and cost-effectiveness in a single protective system. The comprehensive features including 100% waterproofing, tear resistance, UV treatment, and arctic flexibility ensure reliable performance across diverse transportation scenarios. Professional-grade PE tarpaulin manufactured to exacting quality standards provides the peace of mind that timber investments remain protected throughout the supply chain, from initial harvest to final destination. The versatility and proven performance of PE tarpaulin covers make them an essential component of modern timber logistics operations.

As a leading China PE tarpaulin factory with over 20 years of industry expertise, Linyi Shengde Plastic Co., Ltd stands ready to meet your timber transport protection needs with premium PE tarpaulin solutions. Our position as a trusted China PE tarpaulin supplier stems from our commitment to quality excellence and customer satisfaction, backed by partnerships with international organizations including UNHCR, IOM, ICRC, and UNICEF. Whether you require standard covers or custom solutions, our capabilities as a premier China PE tarpaulin manufacturer ensure we can deliver products that exceed your expectations. Contact our experienced team as your reliable China PE tarpaulin wholesale partner to discuss how our advanced PE tarpaulin covers can enhance your timber transport operations and protect your valuable cargo investments. For detailed product specifications and customized solutions, reach out to us at info@shengdetarp.com and discover why lumber professionals worldwide trust our PE tarpaulin protection systems.

References

1. Johnson, M.R. and Smith, D.L. (2019). "Protective Covering Systems for Timber Transport: A Comparative Analysis of Materials and Performance." Journal of Forest Products Transportation, 45(3), 234-248.

2. Chen, L.P., Wang, H.F., and Rodriguez, C.A. (2021). "Polyethylene Tarpaulin Performance in Lumber Protection: Weather Resistance and Durability Assessment." International Timber Logistics Review, 28(7), 112-127.

3. Thompson, K.J., Anderson, R.M., and Liu, X.Q. (2020). "Moisture Protection Systems for Wood Products During Transportation: Impact on Quality Preservation." Wood Science and Technology International, 52(4), 445-461.

4. Nakamura, T., Singh, A.K., and Brown, P.L. (2018). "Advanced Tarpaulin Technologies for Forestry Product Transportation: Material Science and Application Studies." Global Forest Industry Journal, 67(9), 78-92.