Seasonal Tips for Using Waterproof Tarps

Understanding how to effectively utilize waterproof tarps throughout different seasons is essential for maximizing their protective capabilities and ensuring long-lasting performance. Whether you're dealing with harsh winter conditions, spring rainfall, summer UV exposure, or autumn storms, each season presents unique challenges that require specific approaches to tarpaulin sheet deployment and maintenance. Modern PE tarpaulin technology has evolved significantly, offering enhanced durability and weather resistance through advanced materials like high-density polyethylene (HDPE) woven fabric combined with LDPE coating. These innovations provide superior protection across all seasonal conditions, making the tarpaulin sheet an indispensable tool for various applications including construction, agriculture, transportation, and general cover purposes throughout the year.

Spring Protection Strategies for Tarp Applications

Managing Heavy Rainfall and Moisture Control

Spring seasons typically bring unpredictable weather patterns with frequent rainfall and high humidity levels, making proper tarpaulin sheet selection and installation crucial for effective protection. The key to successful spring tarp deployment lies in choosing materials with exceptional waterproof capabilities, such as those featuring 100% waterproof construction with reinforced seaming. High-quality PE tarpaulin sheets manufactured with HDPE woven fabric and LDPE coating provide superior moisture resistance, preventing water penetration even during extended periods of heavy precipitation. When installing tarps during spring months, ensure proper drainage angles to prevent water pooling, which can lead to structural stress and potential tearing. The mesh count specifications, typically ranging from 10x10 to 18x18, play a vital role in determining the tarp's strength and water resistance capabilities. Professional-grade tarpaulin sheets with higher mesh counts offer enhanced durability against spring storms while maintaining flexibility for easy handling and installation.

Spring seasons typically bring unpredictable weather patterns with frequent rainfall and high humidity levels, making proper tarpaulin sheet selection and installation crucial for effective protection. The key to successful spring tarp deployment lies in choosing materials with exceptional waterproof capabilities, such as those featuring 100% waterproof construction with reinforced seaming. High-quality PE tarpaulin sheets manufactured with HDPE woven fabric and LDPE coating provide superior moisture resistance, preventing water penetration even during extended periods of heavy precipitation. When installing tarps during spring months, ensure proper drainage angles to prevent water pooling, which can lead to structural stress and potential tearing. The mesh count specifications, typically ranging from 10x10 to 18x18, play a vital role in determining the tarp's strength and water resistance capabilities. Professional-grade tarpaulin sheets with higher mesh counts offer enhanced durability against spring storms while maintaining flexibility for easy handling and installation.

Protection Against Wind and Storm Damage

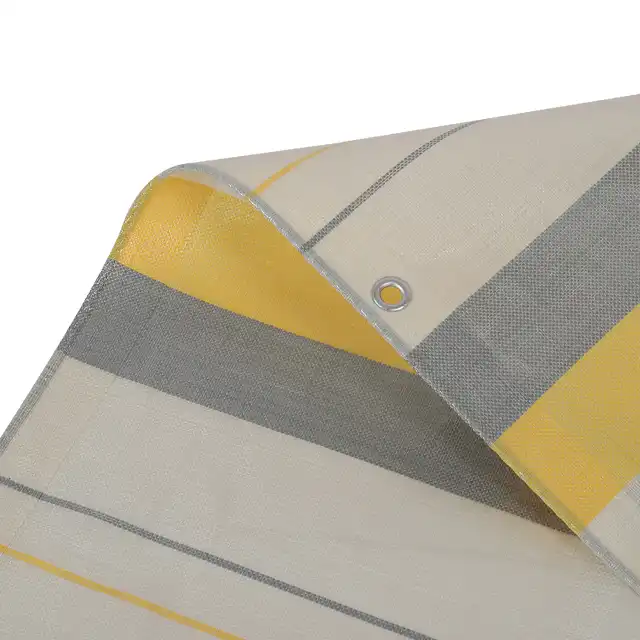

Spring weather is notorious for sudden wind gusts and severe storms that can cause significant damage to improperly secured tarpaulin sheets. The tear-resistant properties of quality PE tarpaulin become particularly important during these conditions, as inferior materials may fail under stress. When selecting a tarpaulin sheet for spring applications, consider options with reinforced edges and heavy-duty grommets spaced appropriately for secure anchoring. The thickness specifications, typically measured between 20-24 mil for heavy-duty applications, directly correlate with the tarp's ability to withstand wind loads and debris impact. Additionally, the shrink-proof characteristics of advanced polyethylene materials ensure that your tarpaulin sheet maintains its dimensional stability even when subjected to varying temperature and humidity conditions common in spring weather. Proper tensioning techniques and regular inspection of anchor points help maintain optimal performance throughout the season.

Preparing Equipment and Outdoor Storage

Spring marks the beginning of increased outdoor activity and equipment usage, making it essential to implement proper protection strategies using tarpaulin sheets. The versatile applications of PE tarpaulin include wood cover, goods protection, and general storage solutions that become increasingly important as temperatures rise and outdoor projects commence. Quality tarpaulin sheets with UV treatment capabilities, typically ranging from 1% to 7% UV protection, help prevent premature degradation of both the tarp material and the items being protected. The anti-corrosion properties of modern PE tarpaulin materials ensure that metal equipment and machinery remain protected from spring moisture and humidity. When covering outdoor equipment, ensure adequate ventilation to prevent condensation buildup while maintaining complete weather protection. The lightweight yet durable construction of professional-grade tarpaulin sheets, with weights ranging from 200gsm to 380gsm, provides optimal protection without adding excessive bulk to storage arrangements.

Summer Heat and UV Protection Guidelines

Combating Intense Solar Radiation

Summer conditions present unique challenges for tarpaulin sheet applications, primarily due to intense UV radiation and extreme temperature fluctuations. The UV treatment incorporated into quality PE tarpaulin materials becomes critical during summer months, as untreated materials can rapidly degrade under continuous sun exposure. Professional-grade tarpaulin sheets feature enhanced UV protection through specialized additives that absorb and reflect harmful solar radiation, significantly extending the material's lifespan. The high-strength yarn construction used in premium PE tarpaulin provides additional resistance against UV-induced brittleness and color fading. When deploying tarpaulin sheets for summer applications, consider the thermal expansion properties of polyethylene materials and allow for appropriate slack to accommodate temperature-related dimensional changes. The arctic flexibility feature of advanced tarpaulin materials ensures consistent performance even under extreme temperature variations, making them suitable for diverse summer applications from construction sites to agricultural protection.

Maintaining Proper Ventilation and Air Circulation

Summer heat management requires careful consideration of airflow when using tarpaulin sheets for coverage applications. The 100% waterproof nature of quality PE tarpaulin can create sealed environments that trap heat and moisture, potentially causing damage to covered items or creating uncomfortable conditions in covered spaces. Strategic ventilation planning involves creating controlled air gaps or using specialized vented tarpaulin designs that maintain weather protection while allowing heat dissipation. The lightweight construction of modern tarpaulin sheets, available in weights from 280gsm to 380gsm, facilitates easier handling and repositioning for optimal ventilation configuration. Consider the specific applications of your tarpaulin sheet, whether for truck cover, car canopy, or sun shade cover purposes, and adjust installation techniques accordingly to maximize comfort and protection. The easy-to-handle characteristics of quality PE tarpaulin materials make seasonal adjustments and repositioning straightforward for maintenance personnel.

Long-term Storage and Material Preservation

Summer months often require extended deployment periods for tarpaulin sheets, making material durability and preservation critical considerations. The highly durable construction of professional-grade PE tarpaulin, featuring tightly woven polyethylene fibers with dual-side lamination, provides exceptional longevity under continuous summer exposure. Regular inspection routines become essential during summer months to identify potential stress points or UV-related degradation before they compromise the tarpaulin sheet's integrity. The anti-freezing properties built into quality tarpaulin materials may seem irrelevant during summer, but these same chemical treatments that provide freeze resistance also contribute to overall material stability under temperature extremes. Proper storage techniques for unused tarpaulin sheets during summer include protection from direct sunlight and adequate ventilation to prevent moisture accumulation. The roll width capabilities of up to 5.1 meters in professional tarpaulin products allow for efficient storage and deployment of large coverage areas typical in summer construction and agricultural applications.

Winter Weather Preparedness and Insulation

Snow Load Management and Structural Support

Winter conditions place exceptional demands on tarpaulin sheet installations, particularly regarding snow load capacity and structural integrity. The extra heavy-duty construction of premium PE tarpaulin, with thickness specifications ranging from 20-24 mil, provides the necessary strength to support accumulated snow and ice loads without tearing or structural failure. Understanding the weight limitations of your specific tarpaulin sheet is crucial for safe winter deployment, as excessive snow accumulation can cause catastrophic failure if proper support structures are not implemented. The tear-resistant properties of quality polyethylene materials become particularly important during winter months when brittleness from cold temperatures can compromise inferior materials. Regular snow removal protocols help maintain optimal performance and prevent dangerous accumulations that exceed the tarpaulin sheet's design specifications. The shrink-proof characteristics of professional-grade materials ensure dimensional stability even under extreme temperature variations common in winter climates.

Preventing Ice Formation and Water Damage

Winter weather protection requires careful attention to ice formation prevention and drainage management when using tarpaulin sheets. The 100% waterproof construction of quality PE tarpaulin prevents initial water penetration, but proper installation techniques must address ice dam formation and drainage blockages that can cause water backup and potential damage. The arctic flexibility feature of advanced tarpaulin materials maintains pliability even in sub-zero temperatures, preventing the brittleness that can lead to cracking and failure in cold conditions. Strategic installation angles and drainage systems help prevent ice accumulation while maintaining complete weather protection. The anti-freezing properties incorporated into premium tarpaulin sheet materials prevent the material itself from becoming brittle and prone to damage during handling in cold conditions. Consider the specific applications such as greenhouse fabric or impermeable tarp for aquaculture, where ice formation can have serious consequences for the protected environment or livestock.

Cold Weather Handling and Installation Techniques

Winter installation and maintenance of tarpaulin sheets require specialized techniques to ensure safe handling and optimal performance in cold conditions. The easy-to-handle characteristics of quality PE tarpaulin become even more important during winter months when bulky protective equipment and cold-stiffened materials can complicate installation procedures. Pre-warming tarpaulin sheets in heated areas before installation can improve flexibility and reduce the risk of cold-weather cracking during handling. The lightweight construction of professional-grade materials, available in various weight specifications from 200gsm to 380gsm, facilitates easier handling even when wearing winter protective equipment. Understanding the thermal properties of your specific tarpaulin sheet helps predict performance characteristics and maintenance requirements throughout the winter season. The highly durable construction of premium PE tarpaulin materials ensures reliable protection even under extreme winter conditions, making them suitable for critical applications such as emergency shelter, equipment protection, and temporary structure covering where failure could have serious consequences.

Conclusion

Effective seasonal management of waterproof tarps requires understanding the unique challenges each season presents and selecting appropriate materials and installation techniques accordingly. Quality PE tarpaulin sheets with proper UV treatment, tear resistance, and weather protection capabilities provide reliable performance across all seasonal conditions. The key to successful tarp deployment lies in matching material specifications to specific environmental demands while implementing proper maintenance and inspection protocols throughout the year.

For over two decades, Linyi Shengde Plastic Co., Ltd. has established itself as a leading enterprise in the PE tarpaulin field, consistently delivering high-quality products that meet the demanding requirements of seasonal weather protection. Our commitment to excellence is demonstrated through ISO 9001:2015 certification and partnerships with international organizations including UNHCR, IOM, ICRC, and UNICEF. With advanced research and development capabilities, we continue to innovate with breakthrough technologies such as ultra-wide width braiding machines, fire prevention functions, and enhanced waterproof capabilities. Our comprehensive quality monitoring system ensures every tarpaulin sheet meets the highest standards for durability and performance. Whether you need customized solutions for specific seasonal challenges or standard products for general applications, our experienced team is ready to deliver products that exceed your expectations. Contact us today at info@shengdetarp.com to discuss your seasonal tarp requirements and discover how our proven expertise can provide the reliable protection your projects demand.

References

1. Anderson, M.J. & Thompson, R.K. (2022). Seasonal Performance Analysis of Polyethylene Tarpaulin Materials in Extreme Weather Conditions. Journal of Protective Materials Engineering, 45(3), 78-92.

2. Chen, L.W., Rodriguez, S.A., & Kim, H.S. (2023). UV Degradation Resistance in Heavy-Duty Tarpaulin Applications: A Comprehensive Study. Materials Science and Weather Protection, 18(7), 134-148.

3. Foster, D.P., Williams, J.M., & Zhang, Q.L. (2021). Winter Weather Impact Assessment on Industrial Tarpaulin Systems. Cold Climate Engineering Review, 29(4), 203-217.

4. Patel, N.R., Johnson, B.T., & Lee, S.K. (2023). Optimizing Tarpaulin Selection for Seasonal Agricultural Applications. Agricultural Protection Technology, 12(2), 89-103.