Tips for Making Your Tarpaulin More Durable

Picture this: you've invested in what you thought was a high-quality tarpaulin, only to find it deteriorating within months due to harsh weather conditions, improper handling, or inadequate maintenance. This frustrating scenario costs businesses and individuals thousands of dollars annually in replacement costs and potential damage to valuable equipment or goods. Understanding how to maximize your durable tarpaulin's lifespan isn't just about basic care – it requires strategic maintenance, proper installation techniques, and selecting the right materials from the start. The key lies in implementing proven durability enhancement methods that can extend your tarp's service life by years, not months.

Understanding Durable Tarpaulin Materials and Construction

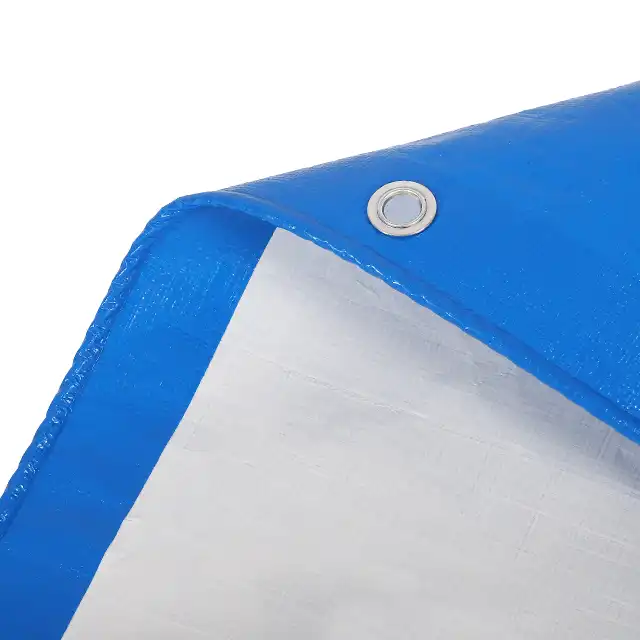

The foundation of any long-lasting tarpaulin begins with understanding the materials and construction methods that contribute to its durability. High-quality durable tarpaulin products are engineered using advanced materials science principles that maximize resistance to environmental stressors while maintaining flexibility and strength. Modern polyethylene tarpaulins, particularly those made from high-density polyethylene (HDPE) woven fabric with low-density polyethylene (LDPE) coating, represent the pinnacle of tarpaulin technology. The construction process involves creating a fabric from high-density, tightly woven polyethylene fibers that are then laminated on both sides to create a waterproof barrier. This dual-layer approach ensures that even if the outer coating experiences minor damage, the inner fabric maintains structural integrity. Professional manufacturers utilize yarn thicknesses ranging from 400D to 2500D, allowing for customization based on specific application requirements. The weaving process typically employs mesh counts between 10x10 and 14x14, with thickness variations from 7 to 12 mil depending on the intended use. Quality durable tarpaulin incorporates UV treatment ranging from 1% to 7%, providing essential protection against harmful solar radiation that can cause material degradation over time. This treatment involves adding UV-resistant compounds during the manufacturing process, creating a molecular barrier that prevents ultraviolet rays from breaking down the polymer chains that give the material its strength and flexibility.

-

Advanced Manufacturing Techniques

Modern production facilities employ sophisticated manufacturing techniques that significantly enhance durable tarpaulin performance. High-tech extruding machines create uniform yarn thickness, while Korea-imported automatic water-jet looms ensure consistent weave patterns that eliminate weak points in the fabric structure. The coating process utilizes professional-grade coating machines operated by skilled technicians who monitor temperature, pressure, and chemical composition to achieve optimal adhesion between layers. The finishing process involves heat-sealing techniques that create strong, waterproof seams capable of withstanding extreme stress conditions. Professional manufacturers employ multiple heat-sealing machines operating at precisely controlled temperatures to ensure uniform seal quality across the entire product line. This attention to manufacturing detail directly correlates with the final product's durability and performance characteristics.

Proper Installation Techniques for Maximum Durability

Correct installation represents one of the most critical factors in maximizing durable tarpaulin lifespan, yet it's often overlooked by users focused solely on the material quality itself. Professional installation requires understanding load distribution, tension management, and environmental factor mitigation. The goal is creating a secure covering system that minimizes stress concentrations while allowing for natural material movement during temperature fluctuations and wind events. Proper tensioning techniques require achieving optimal tightness – secure enough to prevent wind-induced flapping that causes fatigue damage, but not so tight that normal thermal expansion creates excessive stress on attachment points. Industry professionals recommend implementing gradual tensioning procedures, starting from the center and working toward the edges in a systematic pattern that distributes stress evenly across the entire surface area. Edge protection represents another crucial installation consideration. Sharp edges, protruding hardware, and abrasive surfaces can create concentrated wear points that lead to premature failure. Installing protective padding, edge guards, or rubbing strips at contact points significantly extends durable tarpaulin service life by eliminating these destructive friction forces.

-

Strategic Attachment Point Selection

Selecting appropriate attachment points requires careful analysis of structural loading and environmental conditions. Attachment points should be positioned to minimize stress concentrations while providing adequate support for expected wind and weather loads. Professional installers typically space attachment points at intervals calculated based on tarpaulin size, material properties, and local weather conditions. The use of proper hardware is equally important. Stainless steel grommets, reinforced with additional fabric layers, provide superior holding power compared to basic eyelet installations. Professional-grade tie-down systems distribute loads across larger areas, reducing the likelihood of tear-out failures that compromise the entire installation.

Environmental Protection and Maintenance Strategies

Environmental protection encompasses a comprehensive approach to shielding durable tarpaulin from destructive forces while implementing maintenance procedures that address wear before it becomes critical. Understanding how different environmental factors affect tarpaulin materials allows for proactive protection strategies that significantly extend service life. UV protection represents the primary concern for outdoor applications. Even UV-treated durable tarpaulin materials benefit from additional protective measures during periods of intense solar exposure. Strategic positioning to minimize direct sunlight exposure during peak hours, combined with periodic application of UV-protective treatments, can double or triple the effective service life of quality tarpaulins. Chemical exposure prevention requires understanding the specific chemicals present in the operating environment and their potential effects on tarpaulin materials. While high-quality durable tarpaulin exhibits excellent chemical resistance, prolonged exposure to petroleum products, industrial solvents, or highly acidic conditions can cause gradual degradation. Implementing protective barriers or regular cleaning protocols removes potentially damaging substances before they can penetrate the material structure.

-

Seasonal Maintenance Protocols

Seasonal maintenance protocols address the cyclical stresses imposed by changing weather conditions and operational requirements. Pre-winter preparations should include thorough cleaning to remove accumulated debris, inspection of all attachment points and hardware, and application of protective treatments designed to enhance cold-weather performance. Many durable tarpaulin failures occur during winter months when materials become less flexible and more susceptible to impact damage. Spring maintenance focuses on repairing any winter damage, re-tensioning systems that may have loosened during freeze-thaw cycles, and preparing the covering system for increased UV exposure and potential storm activity. Summer maintenance emphasizes UV protection renewal and ventilation improvements to prevent heat-related degradation, while fall preparations concentrate on securing systems against increased wind loads and precipitation.

Repair and Restoration Techniques

Professional repair techniques can restore damaged durable tarpaulin to near-original performance levels while preventing small problems from developing into major failures. Understanding which damages are repairable versus those requiring replacement helps optimize maintenance budgets and ensures continued protection of valuable assets. Minor punctures and tears often respond well to professional patching techniques using compatible materials and appropriate adhesives. The key to successful repairs lies in proper surface preparation, selection of matching materials, and application of sufficient overlap to distribute stress away from the damaged area. Quality repair patches should extend at least two inches beyond the damaged area in all directions and be applied to clean, dry surfaces for optimal adhesion. Seam repairs require more specialized techniques but often prove more cost-effective than complete replacement. Professional repair services utilize heat-welding equipment capable of creating watertight seams that match or exceed original factory specifications. These repairs often prove more durable than the original seams due to improved techniques and materials developed since the original manufacturing date.

-

Preventive Restoration Services

Preventive restoration services address material degradation before it results in functional failure. These services typically include deep cleaning to remove embedded contaminants, reapplication of protective coatings, and reinforcement of high-stress areas with additional material layers. Professional restoration can extend durable tarpaulin service life by 50% or more compared to basic maintenance alone. Advanced restoration techniques include UV damage reversal through specialized chemical treatments, flexibility restoration through polymer conditioning, and waterproofing renewal using modern sealant technologies. These services prove particularly valuable for large or expensive tarpaulin installations where replacement costs would be substantial.

Storage and Handling Best Practices

Proper storage and handling practices significantly impact durable tarpaulin longevity, particularly for seasonal applications where materials spend extended periods in storage between uses. Professional storage techniques prevent common problems such as mold growth, material bonding, UV degradation, and mechanical damage that can occur during storage periods. Climate-controlled storage represents the gold standard for valuable durable tarpaulin materials. Maintaining consistent temperature and humidity levels prevents the expansion and contraction cycles that can weaken material fibers over time. Professional storage facilities maintain temperatures between 50-70°F with relative humidity levels of 40-60% to optimize material preservation. Folding techniques require special consideration to prevent permanent creases and stress concentrations that weaken the material structure. Professional storage protocols recommend rolling rather than folding whenever possible, using cores of appropriate diameter to prevent tight radius bends that can cause fiber damage. When folding becomes necessary, padding should be used at fold lines to distribute stress across wider areas.

-

Inventory Management Systems

Professional inventory management systems track usage patterns, maintenance schedules, and replacement needs to optimize durable tarpaulin investments. These systems help identify materials approaching end-of-life before failures occur, allowing for planned replacements that prevent costly emergency situations. Digital tracking systems can monitor individual tarpaulin performance, maintenance history, and repair costs to identify trends that inform future purchasing decisions. This data-driven approach helps optimize material selection and maintenance protocols based on actual performance rather than manufacturer specifications alone.

Conclusion

Maximizing durable tarpaulin lifespan requires a comprehensive approach combining quality material selection, professional installation, proactive maintenance, and proper storage practices. By implementing these proven strategies, users can extend their tarpaulin service life significantly while maintaining optimal protection for valuable assets and equipment.

Cooperate with Linyi Shengde Plastic Co., Ltd.

As a leading China durable tarpaulin manufacturer established in 2003, Linyi Shengde Plastic Co., Ltd. has built an exceptional reputation through two decades of delivering high quality durable tarpaulin products to customers worldwide. Our company operates from a 60,000 square meter facility with registered capital of RMB 60 Million, positioning us as the premier China durable tarpaulin supplier in the industry.

Our manufacturing capabilities include 30+ high-tech extruding machines, 400+ Korea-imported automatic water-jet looms, and 4 units of large fabric coating machines operated by professional technicians. This advanced equipment enables us to produce durable tarpaulin for sale with fabric widths from 1.5m to 5m without joints, weights ranging from 65gsm to 280gsm, and thicknesses from 7-12 mil. Our monthly capacity exceeds 4000MT, making us a reliable China durable tarpaulin wholesale partner for businesses of all sizes.

Our commitment to quality management through ISO 9001:2015 certification and partnerships with UNHCR, IOM, ICRC, and UNICEF demonstrate our dedication to excellence. With products exported to over 30 countries and comprehensive OEM/ODM capabilities, we offer competitive durable tarpaulin price while maintaining superior quality standards. Contact our China durable tarpaulin factory at info@shengdetarp.com for customized solutions that meet your specific requirements.

FAQ

Q: How often should I inspect my durable tarpaulin for damage?

A: Inspect your tarpaulin monthly during active use and before/after severe weather events to identify potential issues early.

Q: What's the best way to clean a heavily soiled durable tarpaulin?

A: Use mild detergent with lukewarm water, scrub gently with a soft brush, rinse thoroughly, and ensure complete drying before storage.

Q: Can UV damage to tarpaulins be reversed?

A: Minor UV damage can be treated with specialized restoration products, but severe UV degradation typically requires material replacement.

Q: How do I determine when a tarpaulin needs replacement versus repair?

A: Replace when damage covers more than 10% of the surface area, seams are failing, or material has lost significant flexibility and strength.

References

1. "Tarpaulin Materials and Construction Standards" - American Society for Testing and Materials (ASTM), Technical Committee D13

2. "Industrial Fabric Maintenance and Longevity" - Industrial Fabrics Association International, Research Division

3. "Polymer Degradation and UV Protection in Outdoor Applications" - Journal of Applied Polymer Science, Materials Research Institute

4. "Heavy Duty Tarpaulin Performance Standards" - International Organization for Standardization (ISO), Technical Committee TC 38