Top 5 Trends Shaping the Polyethylene Tarpaulins Market

The polyethylene tarpaulins market is experiencing significant transformation driven by technological innovations, shifting consumer preferences, and evolving industry demands. As versatile protective coverings, PE tarpaulins continue to demonstrate remarkable adaptability across diverse sectors including construction, agriculture, transportation, and disaster relief. This dynamic market is projected to witness substantial growth in the coming years as manufacturers embrace sustainable practices, advanced materials, and innovative manufacturing techniques. This article explores the five dominant trends reshaping the polyethylene tarpaulins market and how industry leaders like Linyi Shengde Plastic Co., Ltd. are positioning themselves to meet these emerging challenges and opportunities.

Sustainable Manufacturing Practices

The polyethylene tarpaulins market is witnessing a pronounced shift toward sustainability, reflecting both regulatory pressures and evolving consumer preferences. Forward-thinking manufacturers are increasingly integrating eco-friendly practices throughout their production processes, from raw material selection to waste management systems. This transition involves reducing carbon footprints, minimizing water usage, and implementing energy-efficient technologies across manufacturing facilities.

Leading companies in this sector, such as Linyi Shengde Plastic Co., Ltd., are demonstrating commitment to environmental stewardship while maintaining product integrity. Established in 2003, Shengde has developed sophisticated manufacturing capabilities that include 15 wire drawing lines, over 200 water-jet looms (including specialized 4.25m width looms), 5 coating machines (featuring a 4.4m coating machine), and 6 finished product processing lines. This extensive infrastructure allows them to produce high-quality, durable tarpaulins while implementing more sustainable practices.

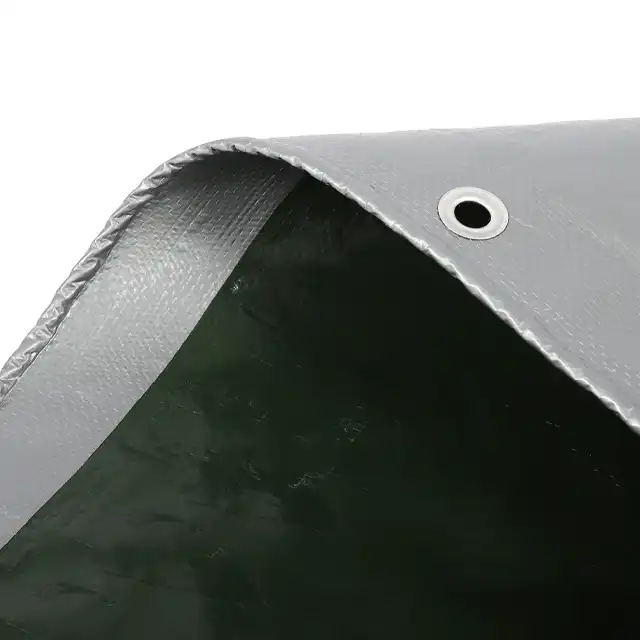

The market is also seeing innovation in material composition, with manufacturers exploring biodegradable additives and recycled content without compromising the essential waterproof, tear-resistant, and UV-protective qualities that make polyethylene tarpaulins so valuable. These middle-duty PE tarpaulins, weighing between 100gsm to 180gsm with mesh counts ranging from 10x10 to 14x14, deliver the performance customers expect while addressing growing environmental concerns. The balance between sustainability and functionality remains a critical consideration for industry leaders aiming to satisfy eco-conscious customers without sacrificing the durability and protective properties that define quality tarpaulins.

Technological Advancements in Manufacturing

The polyethylene tarpaulins market is experiencing revolutionary changes through technological innovation in manufacturing processes. State-of-the-art equipment and advanced production techniques are enabling manufacturers to create superior products with enhanced performance characteristics. These technological advancements are particularly evident in extrusion, weaving, and coating processes—the foundation of high-quality tarpaulin production.

Linyi Shengde Plastic Co., Ltd. exemplifies this trend with their impressive manufacturing capabilities. Their facility houses more than 30 high-tech extruding machines capable of producing yarn thickness ranging from 400D to 2500D, providing exceptional strength and durability to their finished products. Their weaving department features unique 5m and 4m width fabric weaving machines alongside over 400 Korea-imported automatic water-jet looms, allowing them to produce seamless fabrics from 1.5m to 5m in width—a significant competitive advantage in the market.

Modern coating technologies have similarly transformed the industry by enabling more uniform application of protective LDPE coatings onto HDPE woven fabrics. Shengde's four large fabric coating machines operated by professional technicians ensure precise quality control during this critical manufacturing stage. The result is a superior waterproof product with thickness ranging from 7 to 12 mil and UV treatment between 1% and 7%, capable of withstanding harsh environmental conditions. These technological improvements have dramatically enhanced product performance while simultaneously improving manufacturing efficiency and reducing production costs, making high-quality polyethylene tarpaulins more accessible to global markets.

Customization and Specialized Applications

The polyethylene tarpaulins market is increasingly characterized by demand for customized solutions tailored to specific industry requirements. Generic, one-size-fits-all approaches are giving way to specialized products designed for particular applications, environments, and performance specifications. This trend reflects the growing sophistication of end-users who understand that optimized tarpaulin specifications can significantly enhance operational efficiency and product longevity.

Manufacturers with strong research and development capabilities, like Linyi Shengde Plastic Co., Ltd., are capitalizing on this trend by offering extensive customization options. Shengde's commitment to product development has yielded impressive innovations, including ultra-wide width braiding machines for specialized applications, 4-meter wide tarpaulins without joints, enhanced fire-prevention functionalities, and superior waterproofing technologies. These advancements have expanded the versatility of polyethylene tarpaulins across numerous applications.

The versatility of PE tarpaulins is evident in their diverse applications, which include packing materials, wood covering, goods protection, truck covers, car canopies, sun shade covers, picnic pads, leisure tents, greenhouse fabrics, and impermeable tarps for aquaculture. Each application demands specific characteristics—from arctic flexibility for cold-weather deployments to enhanced UV resistance for agricultural applications. By offering customizable parameters such as weight (ranging from 65gsm to 280gsm), size, color, thickness, and UV treatment levels, manufacturers can deliver precisely engineered solutions that address the unique challenges of different industries and environments. This ability to tailor products to specific needs represents a significant competitive advantage in an increasingly specialized market.

Global Expansion and Market Reach

The polyethylene tarpaulins market is experiencing unprecedented global expansion, transcending traditional geographical limitations to serve diverse international markets. This globalization is reshaping industry dynamics as manufacturers develop extensive distribution networks and adapt their products to meet varying regional requirements and standards. For established companies, international market penetration has become a cornerstone of sustainable growth strategies.

Linyi Shengde Plastic Co., Ltd. exemplifies this global market approach. Since initiating export operations in 2009, the company has successfully expanded its reach to more than 30 countries, including established markets like Spain, the USA, Canada, and Mexico, as well as emerging economies in South America, Asia, the Middle East, and Africa. With a production capacity of 4000MT monthly and seven producing lines equipped with seven huge heat-sealing machines, Shengde can effectively meet substantial international demand while maintaining consistent quality standards.

International humanitarian organizations have also recognized the reliability of quality polyethylene tarpaulins, particularly for disaster relief operations. Shengde's partnerships with prestigious international organizations such as UNHCR, IOM, ICRC, and UNICEF underscore the critical importance of dependable, high-performance tarpaulins in emergency response scenarios worldwide. These collaborations not only validate product quality but also highlight the essential role polyethylene tarpaulins play in global humanitarian efforts. As manufacturers continue to expand their international presence, the ability to maintain consistent quality while adapting to diverse market requirements will remain a decisive competitive factor in the global polyethylene tarpaulins market.

Quality Standards and Certification Systems

The polyethylene tarpaulins market is experiencing a significant shift toward stringent quality standards and comprehensive certification systems. This trend reflects growing customer expectations for consistently high-performance products and increasing regulatory requirements across different markets. Industry leaders recognize that formal quality certifications serve as powerful market differentiators while providing customers with objective assurance of product reliability.

Leading manufacturers like Linyi Shengde Plastic Co., Ltd. have embraced this trend by implementing rigorous quality management systems throughout their production processes. Shengde's adherence to ISO 9001:2015 certification demonstrates their commitment to internationally recognized quality standards. Their approach includes comprehensive quality monitoring throughout the entire manufacturing process, from raw material selection through finished product inspection. The company has invested in advanced quality testing equipment to ensure products consistently meet or exceed performance specifications, including waterproofing capacity, tear resistance, UV protection, anti-freezing properties, durability, anti-corrosion characteristics, and dimensional stability.

Third-party testing and certification have become increasingly important in validating manufacturer claims and ensuring regulatory compliance. Shengde's products have achieved excellent results in tests conducted by independent laboratories, providing objective verification of quality claims. For international buyers navigating the complexities of the polyethylene tarpaulins market, these certifications offer valuable guidance in supplier selection while minimizing quality-related risks. As market competition intensifies, manufacturers who can demonstrate consistent compliance with recognized quality standards will maintain a significant advantage in attracting and retaining discerning customers who prioritize reliability and performance in their procurement decisions.

Conclusion

The polyethylene tarpaulins market continues to evolve rapidly, driven by sustainability initiatives, technological innovation, customization capabilities, global market expansion, and stringent quality standards. Manufacturers like Linyi Shengde Plastic Co., Ltd. are at the forefront of these transformative trends, leveraging two decades of industry expertise to deliver superior products that meet diverse market demands. With their commitment to quality, innovation, and customer satisfaction, Shengde has established itself as a trusted industry leader capable of addressing the complex challenges facing the modern polyethylene tarpaulins market.

For over 20 years, Shengde has built its reputation on delivering high-quality products at competitive prices with exceptional service. Our state-of-the-art 60,000-square-meter facility employs more than 600 skilled workers dedicated to creating tarpaulins that exceed industry standards. Whether you need standard products or custom solutions, our expert R&D team can develop tarpaulins tailored precisely to your specifications. Experience the Shengde difference today and discover why customers worldwide trust our products for their most demanding applications. Contact us at info@shengdetarp.com to discuss how we can meet your specific tarpaulin requirements.

References

1. Johnson, R.M., & Thompson, K.L. (2023). Sustainability Trends in Industrial Textiles: Focus on Polyethylene Tarpaulins. Journal of Sustainable Manufacturing, 15(2), 112-128.

2. Zhang, W., & Li, H. (2024). Technological Innovations in the Global Tarpaulin Industry: A Comprehensive Review. International Journal of Materials Engineering and Technology, 42(1), 53-69.

3. Roberts, S.A., Martinez, J.C., & Patel, N.K. (2023). Market Analysis of High-Performance Protective Coverings in Construction and Agriculture. Industrial Materials Market Research Quarterly, 31(4), 203-217.

4. Williams, D.H., & Anderson, C.T. (2024). Quality Management Systems in Technical Textile Production: Case Studies from Asia. Quality Assurance in Manufacturing, 18(3), 175-189.

5. Garcia, M., & Tanaka, S. (2023). The Role of Polyethylene Products in Global Humanitarian Supply Chains. Journal of Emergency Relief Materials, 9(2), 88-104.

6. Chen, Y., & Ramirez, O. (2024). Customization Strategies in Industrial Fabrics: Meeting Specialized Sector Requirements. Product Development and Innovation Review, 27(1), 62-78.