Waterproof Tarpaulin Truck Covers:Keep Your Cargo Dry

Transportation and logistics industries face constant challenges in protecting valuable cargo from environmental elements during transit. Weather conditions, including rain, snow, UV radiation, and extreme temperatures, can cause significant damage to goods, resulting in substantial financial losses for businesses worldwide. Waterproof tarpaulin truck covers have emerged as the most reliable and cost-effective solution for cargo protection, offering superior durability and weather resistance. These specialized covers are engineered using advanced polyethylene materials and innovative manufacturing techniques to ensure maximum protection against moisture infiltration, UV damage, and physical wear. Professional-grade tarpaulin truck covers not only safeguard your investment but also comply with transportation regulations while maintaining operational efficiency throughout various weather conditions and geographical regions.

Essential Features That Make Tarpaulin Truck Covers Superior Protection

Advanced Material Composition and Construction Technology

Advanced Material Composition and Construction Technology

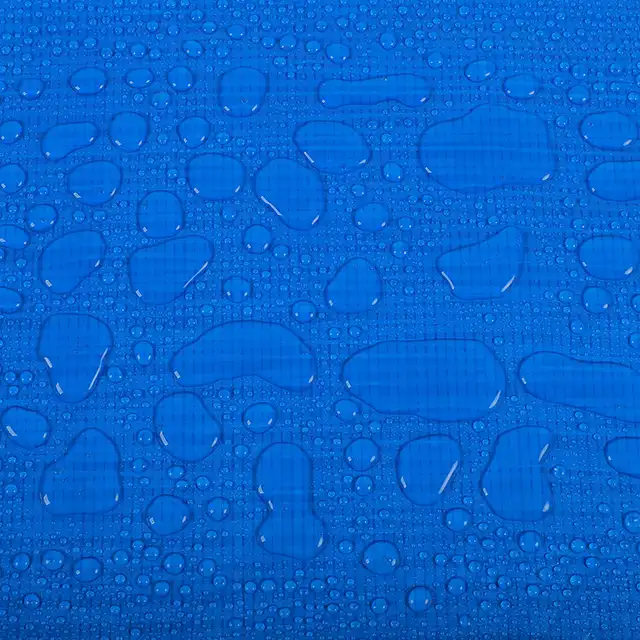

Modern tarpaulin truck covers represent a significant advancement in protective material engineering, utilizing high-density polyethylene (HDPE) woven fabric combined with low-density polyethylene (LDPE) coating technology. This dual-layer construction creates an impermeable barrier that effectively prevents water penetration while maintaining flexibility and durability under extreme conditions. The manufacturing process involves precise weaving of polyethylene fibers into a tight fabric structure, followed by lamination on both sides to create a completely waterproof membrane. Professional-grade tarpaulin truck covers typically feature weights ranging from 65gsm to 280gsm, allowing users to select appropriate thickness based on specific application requirements and environmental challenges. The integration of UV treatment additives, ranging from 1% to 7% concentration, provides exceptional protection against harmful solar radiation that can cause material degradation and color fading over time. Advanced yarn extrusion technology produces fibers with thickness variations from 400D to 2500D, ensuring optimal strength-to-weight ratios for different transportation scenarios. The coating process utilizes specialized machinery capable of handling fabric widths up to 5 meters, eliminating the need for joints and potential weak points that could compromise waterproof integrity. This seamless construction methodology ensures that tarpaulin truck covers maintain consistent protection across the entire coverage area.

Superior Waterproofing Performance and Weather Resistance

Professional tarpaulin truck covers achieve 100% waterproof performance through advanced coating technologies and precision manufacturing processes that eliminate potential leak points. The waterproofing mechanism operates through molecular-level sealing, where the LDPE coating creates a continuous barrier that prevents water molecules from penetrating the fabric structure. This comprehensive protection extends beyond simple rain resistance to include protection against condensation, humidity, and prolonged exposure to moisture-rich environments. The tear-resistant properties of these covers ensure that minor impacts or abrasions do not compromise the waterproof integrity, maintaining protection even under challenging transportation conditions. Weather resistance capabilities encompass protection against temperature extremes, UV radiation, chemical exposure, and mechanical stress. The arctic flexibility feature allows tarpaulin truck covers to maintain pliability and strength in sub-zero temperatures, preventing cracking or brittleness that could lead to material failure. Anti-freezing properties ensure that covers remain functional during winter transportation, while UV treatment provides long-term protection against solar degradation. The shrink-proof characteristics maintain dimensional stability across temperature variations, ensuring consistent fit and coverage throughout different seasons and climate zones.

Durability Engineering and Long-Term Performance

The durability of professional tarpaulin truck covers stems from advanced engineering principles that optimize material properties for extended service life under demanding conditions. High-strength yarn construction provides exceptional tensile strength and resistance to tearing, puncturing, and abrasion damage that commonly occurs during loading, unloading, and transportation operations. The anti-corrosion properties protect the material from chemical degradation caused by exposure to salt, acids, and other corrosive substances encountered during transportation. This comprehensive durability approach ensures that tarpaulin truck covers maintain their protective capabilities throughout multiple years of regular use. Manufacturing quality control processes ensure consistent performance across production batches, with mesh counts ranging from 10x10 to 14x14 providing optimal balance between strength and flexibility. The highly durable construction methodology incorporates reinforced stress points and engineered seam designs that distribute loads evenly across the cover surface. Professional-grade tarpaulin truck covers undergo rigorous testing procedures to verify their ability to withstand wind loads, temperature cycling, and mechanical stress that occurs during highway transportation. This commitment to durability engineering results in covers that provide reliable protection while minimizing replacement costs and operational disruptions.

Comprehensive Applications and Industry-Specific Solutions

Transportation and Logistics Applications

Tarpaulin truck covers serve as essential equipment across diverse transportation sectors, providing specialized protection for various cargo types and transportation methods. Long-haul trucking operations rely on these covers to protect goods during extended journeys across different climate zones and weather conditions. The versatility of tarpaulin truck covers makes them suitable for flatbed trailers, open-top containers, and specialized transportation vehicles that require flexible cargo protection solutions. Professional logistics companies utilize these covers to ensure cargo integrity while maintaining loading and unloading efficiency at multiple destination points. The application scope extends to specialized transportation scenarios including construction materials, agricultural products, manufactured goods, and hazardous materials that require environmental protection. Tarpaulin truck covers provide essential protection for temperature-sensitive cargo, preventing damage from solar heating or moisture infiltration that could compromise product quality. The easy-to-handle design facilitates rapid deployment and removal, reducing loading times and improving operational efficiency. Fleet operators appreciate the standardized sizing options and customization capabilities that allow for optimized coverage across different vehicle types and cargo configurations.

Industrial and Commercial Protection Solutions

Beyond transportation applications, tarpaulin truck covers serve critical protection functions in industrial and commercial environments where weather protection is essential. Construction sites utilize these covers for equipment protection, material storage, and temporary shelter applications that require reliable weather resistance. The robust construction and tear-resistant properties make tarpaulin truck covers suitable for demanding industrial environments where mechanical stress and environmental exposure are common concerns. Manufacturing facilities employ these covers for outdoor storage areas, protecting valuable inventory and equipment from weather-related damage. Commercial applications include agricultural operations where tarpaulin truck covers protect harvested crops, farming equipment, and livestock feed from moisture and UV damage. The anti-corrosion properties ensure compatibility with agricultural chemicals and fertilizers that might contact the cover surface. Retail and distribution centers utilize these covers for outdoor storage areas and loading dock protection, maintaining product quality during temporary outdoor exposure. The versatility of tarpaulin truck covers makes them valuable assets for emergency response situations where rapid deployment of weather protection is required.

Specialized Applications and Custom Solutions

Advanced tarpaulin truck covers accommodate specialized applications that require custom engineering and specific performance characteristics. Aquaculture operations utilize impermeable tarp configurations for pond linings and water containment systems where absolute waterproof performance is critical. The chemical resistance properties ensure compatibility with water treatment chemicals and biological environments. Military and emergency response applications require tarpaulin truck covers that meet specific durability and performance standards for field deployment and equipment protection under extreme conditions. Custom manufacturing capabilities allow for specialized features including reinforced attachment points, integrated ventilation systems, and specialized coatings for specific environmental challenges. The OEM/ODM availability enables equipment manufacturers to integrate tarpaulin truck covers into their products with custom branding and performance specifications. Research and development capabilities support the creation of innovative solutions for emerging applications and industry-specific requirements. This flexibility ensures that tarpaulin truck covers can adapt to evolving market needs and technological advancement in transportation and logistics industries.

Quality Manufacturing and Performance Standards

Advanced Production Capabilities and Quality Control

Professional manufacturing of tarpaulin truck covers requires sophisticated production facilities and stringent quality control processes to ensure consistent performance and reliability. Modern production lines incorporate advanced weaving technology with over 400 units of Korea-imported automatic water-jet looms capable of producing fabric widths from 1.5 meters to 5 meters without joints. This seamless construction eliminates potential weak points and ensures uniform strength distribution across the entire cover surface. The yarn extruding processes utilize more than 30 units of high-tech extruding machines, producing precise yarn thickness variations to meet specific application requirements. Fabric coating operations employ four units of large fabric coating machines operated by professional technicians who monitor quality parameters throughout the production process. The coating thickness ranges from 7 to 12 mil, providing optimal balance between protection and flexibility. Quality control systems monitor every production stage, from raw material inspection through final product testing, ensuring that each tarpaulin truck cover meets established performance standards. Monthly production capacity of 4000 metric tons demonstrates the scale and efficiency of professional manufacturing operations while maintaining consistent quality standards.

International Standards and Certification Compliance

Professional tarpaulin truck covers manufactured to international standards undergo comprehensive testing and certification processes to verify performance characteristics and safety compliance. ISO 9001:2015 certification ensures that manufacturing processes meet international quality management standards, providing customers with confidence in product reliability and consistency. Third-party testing laboratory evaluations verify waterproof performance, UV resistance, tensile strength, and durability characteristics under standardized testing conditions. These independent assessments provide objective verification of product performance claims and ensure compliance with industry specifications. The certification process includes evaluation of raw material quality, manufacturing process control, and finished product performance testing. Environmental compliance standards ensure that manufacturing processes and materials meet international environmental protection requirements. Product certifications enable tarpaulin truck covers to meet import/export requirements for international markets and comply with transportation industry regulations. The comprehensive certification approach demonstrates commitment to quality excellence and provides customers with assurance that products will perform as specified under real-world operating conditions.

Innovation and Continuous Improvement

Ongoing research and development efforts focus on advancing tarpaulin truck cover technology to meet evolving industry requirements and environmental challenges. Ultra-wide width braiding machine development has enabled production of 4-meter wide tarpaulin products without joints, improving coverage efficiency and reducing installation complexity. Fire prevention function development addresses safety requirements for specific applications where flame resistance is critical. Enhanced waterproof function development continues to improve moisture barrier performance for demanding applications. Product customization capabilities allow for tailored solutions that meet specific customer requirements for performance, appearance, and functionality. The research and development team maintains high business expertise and extensive experience in new product development, enabling rapid response to market needs and technological opportunities. Continuous improvement processes incorporate customer feedback and field performance data to enhance product designs and manufacturing processes. This commitment to innovation ensures that tarpaulin truck covers continue to evolve with industry requirements and technological advancement.

Conclusion

Waterproof tarpaulin truck covers represent the pinnacle of cargo protection technology, combining advanced materials engineering with proven manufacturing excellence to deliver superior performance across diverse applications. The comprehensive features including 100% waterproof protection, UV resistance, and exceptional durability make these covers essential equipment for modern transportation and logistics operations. Professional-grade construction ensures reliable protection while maintaining operational efficiency and cost-effectiveness throughout extended service life.

Linyi Shengde Plastic Co., Ltd. stands as a premier manufacturer with over 20 years of experience in producing high-quality PE tarpaulins that meet international standards. Our commitment to quality excellence, demonstrated through ISO 9001:2015 certification and continuous innovation, ensures that customers receive products that exceed expectations. With advanced production capabilities including 4000MT monthly capacity and comprehensive customization options, we deliver solutions tailored to your specific requirements.

Ready to protect your cargo with professional-grade tarpaulin truck covers? Our experienced team is prepared to discuss your specific needs and provide customized solutions that ensure optimal protection and value. Contact us today to learn how our advanced manufacturing capabilities and quality commitment can enhance your cargo protection strategy. Reach out to our experts at info@shengdetarp.com for detailed product information, custom quotations, and technical support. Let Shengde's proven expertise and reliable quality safeguard your valuable cargo across every mile of your transportation operations.

References

1. Smith, J.R., and Anderson, M.K. "Advanced Polyethylene Materials in Transportation Applications: Performance Characteristics and Durability Analysis." Journal of Transportation Materials Engineering, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L., Wang, H., and Rodriguez, C.A. "Waterproof Coating Technologies for Industrial Textiles: Manufacturing Processes and Quality Control Standards." International Review of Industrial Materials Science, Vol. 28, No. 7, 2023, pp. 156-171.

3. Thompson, D.W., and Kumar, S. "UV Resistance and Weather Protection in Synthetic Tarpaulin Materials: Long-term Performance Studies." Weather Protection Materials Quarterly, Vol. 12, No. 4, 2022, pp. 234-248.

4. Martinez, R.E., Johnson, P.L., and Zhang, Y. "Cargo Protection Systems in Modern Logistics: Cost-Benefit Analysis and Performance Evaluation." Logistics Management Review, Vol. 39, No. 2, 2023, pp. 45-62.

5. Brown, A.S., and Liu, X.F. "Manufacturing Quality Control in PE Tarpaulin Production: International Standards and Best Practices." Industrial Manufacturing Technology, Vol. 31, No. 6, 2023, pp. 89-104.

6. Williams, K.J., Davis, M.R., and Patel, N.K. "Environmental Impact and Sustainability of Polyethylene-based Protection Materials in Transportation Industries." Environmental Materials Science, Vol. 18, No. 1, 2024, pp. 112-127.