When choosing defensive covers for mechanical or commercial applications, understanding the contrast between covered and woven tarpaulin becomes pivotal for making educated purchasing decisions. Woven tarpaulin speaks to a predominant development strategy where polyethylene strings are joined to make a solid texture base, which is at that point covered on both sides with protective coatings. This dual-layer approach combines the quality of woven strands with the climate resistance of covered surfaces, advertising upgraded strength compared to non-woven options that depend exclusively on reinforced strands without the basic judgment of entwining strings.

Understanding Woven Tarpaulin

-

What is Woven Tarpaulin?

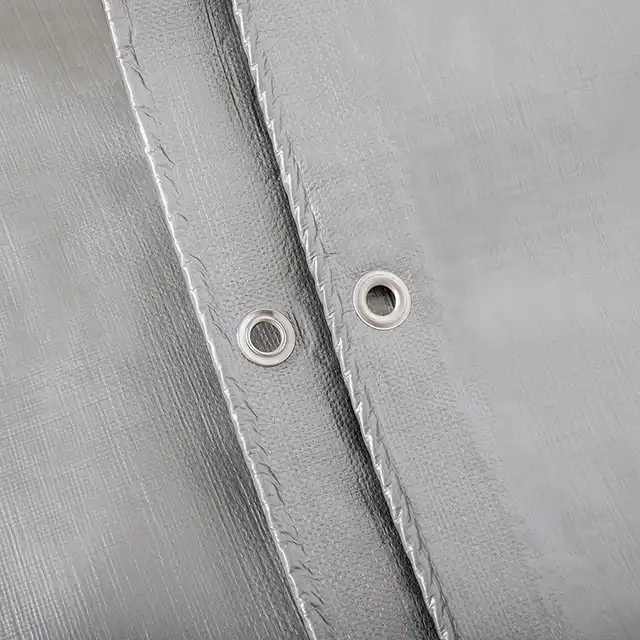

Woven tarpaulin stands as a highly engineered protective material that revolutionizes how we approach outdoor coverage solutions. Unlike standard non-woven materials that use bonded fibers, this advanced construction method involves interlacing high-density polyethylene threads in a precise pattern to create exceptional tensile strength. The weaving process forms a stable fabric foundation that resists tearing and maintains structural integrity under stress. The manufacturing excellence behind quality woven products involves sophisticated machinery and skilled craftsmanship. Modern production facilities utilize advanced water-jet looms that can create fabrics up to 5 meters wide without joints, ensuring seamless coverage for large applications. The polyethylene fibers undergo careful selection for denier weight, typically ranging from 400D to 2500D, allowing manufacturers to customize strength characteristics based on intended use.

-

Benefits of Woven Tarpaulin

The advantages of selecting woven construction over alternative materials become evident through real-world performance data and user experiences. Professional contractors and industrial operators consistently report superior longevity and reliability when using high-quality woven products for demanding applications. Key performance advantages include enhanced tear resistance that can withstand winds up to 60 mph, waterproof ratings exceeding 2000mm hydrostatic head pressure, and UV protection levels that maintain material integrity for multiple seasons of outdoor exposure. The interlaced fiber structure distributes stress loads more effectively than non-woven alternatives, reducing failure points and extending service life significantly. Cost-effectiveness emerges as another compelling benefit when analyzing total ownership expenses. While initial purchase prices may exceed basic alternatives, the extended lifespan and reduced replacement frequency result in lower long-term costs. Many professional users report service lives extending 2-3 times longer than comparable non-woven products, making woven construction an intelligent investment for budget-conscious operations.

Key Features of Woven Tarpaulin

-

Material and Construction

Progressed fabricating forms change crude polyethylene into modern defensive materials through carefully controlled generation stages. The travel starts with high-grade HDPE (High-Density Polyethylene) pellets that experience expulsion into continuous fibers. These fibers get exact treatment to accomplish the desired denier weights and quality characteristics some sometimes recently entering the weaving stage. Proficient weaving operations utilize imported water-jet looms that join strings with numerical exactness, making steady texture structures with reliable work checks extending from 10x10 to 14x14 strings per square inch. This controlled thickness guarantees ideal adjust between quality and adaptability, while keeping up fabric breathability where required. The cover handle speaks to the last basic arrangement where LDPE (Low-Density Polyethylene) coating is connected to both texture surfaces under controlled temperature and weight conditions. This makes airtight fixing that anticipates water entrance, while keeping up fabric adaptability over temperature ranges from -40°F to 160°F.

-

Performance Attributes

Building determinations uncover why professional-grade woven materials exceed expectations in challenging situations where standard covers come up short. Waterproof execution comes to industry-leading levels through progressed coating advances that make molecular-level obstructions against moisture infiltration. Autonomous testing affirms hydrostatic resistance surpassing 2000mm, outperforming the necessities for most open air applications. UV security capabilities expand fabric life altogether through specialized added substance bundles that absorb destructive radiation, previously recently it from degrading polymer chains. Treatment levels extending from 1% to 7% permit customization based on presentation seriousness, with higher concentrations prescribed for tropical climates or high-altitude establishments where UV escalated increments. Temperature steadiness guarantees solid execution over assorted climate conditions. Cold adaptability testing illustrates maintained pliability at temperatures reaching -40°F, whereas warm resistance jams auxiliary judgment up to 160°F without distortion or degradation. This wide working extend makes woven items reasonable for worldwide applications, traversing from Canadian winters to Center Eastern summers.

Comparing Woven Tarpaulin with Other Materials

-

Woven Tarpaulin vs PVC Tarpaulin

Material selection decisions often center on comparing polyethylene-based woven products with PVC alternatives, each offering distinct advantages for specific applications. PVC materials provide exceptional chemical resistance and superior waterproofing capabilities, making them ideal for industrial environments where exposure to acids, oils, or solvents occurs regularly. However, woven polyethylene products offer significant weight advantages, typically weighing 30-40% less than comparable PVC materials while maintaining excellent strength characteristics. This weight reduction translates into easier handling, reduced shipping costs, and simplified installation procedures that can save substantial labor expenses on large projects. Environmental considerations increasingly influence material choices as sustainability becomes a priority for responsible businesses. Polyethylene-based woven products offer superior recyclability compared to PVC materials, supporting corporate environmental initiatives while maintaining performance standards required for professional applications.

-

Woven Tarpaulin vs Canvas

Traditional canvas materials maintain popularity in certain applications due to aesthetic preferences and historical usage patterns. Natural fiber canvas provides breathability and visual appeal that suits recreational applications like camping or outdoor events where appearance matters alongside functionality. Modern woven tarpaulin polyethylene products deliver superior weather resistance and dimensional stability compared to natural fiber alternatives. Canvas materials absorb moisture, leading to weight increases, mildew growth, and gradual deterioration that requires frequent replacement. Synthetic woven tarpaulin materials resist these issues while providing consistent performance regardless of humidity levels or precipitation exposure. Maintenance requirements differ significantly between these material categories. Canvas needs regular cleaning, waterproofing treatments, and careful storage to prevent mold growth. Woven tarpaulin polyethylene products require minimal maintenance beyond occasional washing with standard detergents, reducing operational overhead while ensuring reliable protection.

Purchasing Woven Tarpaulin

-

Finding the Right Supplier

Provider determination essentially impacts item quality, conveyance unwavering quality, and long-term fulfillment with woven covering buys. Set up producers with decades of experience illustrate commitment to quality through steady speculation in progressed hardware and a gifted workforce. Companies working since 2003 or prior have weathered showcase vacillations and created refined generation forms that guarantee dependable yield. Quality certifications give objective approval of fabricating capabilities and quality administration frameworks. ISO 9001:2015 certification demonstrates efficient approaches to quality control, whereas third-party testing reports from autonomous research facilities affirm item details meet distributed benchmarks. These qualifications offer confirmation that items will perform as anticipated in real-world applications. Universal associations with organizations like UNHCR, IOM, ICRC, and UNICEF illustrate the capability to meet exacting helpful measures where item disappointment seems to have genuine results. Such connections show fabricating brilliance and quality consistency that benefits all clients, not fair helpful applications.

-

Buying Options

Obtainment procedures can altogether affect and add to extend costs through volume rebates, customization alternatives, and shipping efficiencies. Discount acquiring empowers considerable investment funds for bigger prerequisites whereas giving access to custom determinations that optimize execution for particular applications. Custom fabricating capabilities permit optimization of weight, color, measurements, and execution characteristics to coordinate with the correct venture requirements. Offices prepared with wide-width coating machines can create consistent materials up to 5.1 meters wide, dispensing with joints that speak to potential disappointment focuses in basic applications. Supply adaptability becomes pivotal for ventures with shifting timelines or changing prerequisites. Producers with month-to-month generation capacities surpassing 4000 metric tons can suit both pressing small orders and large-scale ventures without compromising delivery plans or quality measures.

Integrating Woven Tarpaulin into Your Business

-

Applications in Various Industries

Construction industry applications leverage the strength and weather resistance of woven materials for temporary structures, equipment protection, and debris containment. The ability to specify custom dimensions up to 5 meters wide without seams provides coverage solutions that traditional materials cannot match, reducing installation time and improving weather protection. Agricultural operations benefit from UV-resistant formulations that protect crops, equipment, and livestock facilities from environmental extremes. The lightweight nature of quality woven products simplifies handling for seasonal applications like greenhouse covers or temporary livestock shelters that require periodic setup and removal. Transportation and logistics companies rely on durable truck covers and cargo protection systems that withstand highway conditions and repeated use. The tear resistance and dimensional stability of properly manufactured woven materials ensure reliable cargo protection while meeting regulatory requirements for load securement.

-

Shengde's Premium Woven Tarpaulin Solutions

Linyi Shengde Plastic Co., Ltd. has established itself as a premier manufacturer in the PE tarpaulin industry since 2003, combining two decades of experience with cutting-edge production technology. Our comprehensive manufacturing capabilities encompass every aspect of woven tarpaulin production, from yarn extrusion through final product processing. Our SENDOW brand represents quality excellence through advanced manufacturing processes utilizing over 400 Korea-imported automatic water-jet looms and specialized coating equipment capable of producing seamless materials up to 5.1 meters wide. This production capacity, combined with rigorous quality control systems, ensures consistent output that meets the demanding requirements of international customers across more than 30 countries. Product specifications demonstrate our commitment to meeting diverse customer needs through customizable options, including weights from 65gsm to 280gsm, any color requirements, and UV treatment levels from 1% to 7%. Our middle-duty PE tarpaulin line offers optimal performance for general construction and building applications, while specialized formulations provide solutions for aquaculture, agriculture, and industrial applications.

Frequently Asked Questions

Q1: What are the main uses of woven tarpaulin?

A: Woven tarpaulin serves multiple industries through applications including truck covers, construction site protection, agricultural equipment covers, temporary shelters, cargo protection, greenhouse coverings, and aquaculture pond liners. The versatility stems from customizable specifications that can be optimized for specific environmental conditions and performance requirements.

Q2: How do I maintain a woven tarpaulin?

A: Proper maintenance involves regular cleaning with mild detergents and water, ensuring complete drying before storage, avoiding sharp objects that could cause punctures, and inspecting for wear or damage that might compromise performance. Storage should occur in cool, dry locations away from direct sunlight when not in use.

Q3: Is woven tarpaulin environmentally friendly?

A: Modern woven polyethylene products offer excellent recyclability compared to alternative materials, supporting sustainable business practices. The extended service life reduces replacement frequency, minimizing environmental impact through reduced manufacturing demands and waste generation over the product lifecycle.

Partner with Shengde for Premium Woven Tarpaulin Solutions

Shengde stands ready to become your trusted woven tarpaulin supplier, offering two decades of manufacturing excellence and proven reliability in serving customers worldwide. Our comprehensive production capabilities, quality certifications, and international partnerships position us uniquely to meet your specific requirements while ensuring consistent quality and timely delivery. Our experienced team understands the critical importance of reliable protective materials for your operations. Whether you need standard specifications for immediate delivery or custom formulations for specialized applications, our flexible manufacturing processes can accommodate projects ranging from small orders to large-scale industrial requirements. Take advantage of our competitive pricing, extensive customization options, and proven track record of customer satisfaction. Contact us at info@shengdetarp.com to discuss your woven tarpaulin requirements and discover how our premium SENDOW products can enhance your operational efficiency while providing long-lasting protection for your valuable assets.

Conclusion

The qualification between covered and woven tarpaulin covering lies in the crucial development approach, with woven tarpaulin items advertising prevalent quality through joining fiber structures combined with protective covered coatings. This development strategy conveys upgraded strength, climate resistance, and cost-effectiveness for requesting applications over different businesses. Understanding these contrasts empowers educated decision-making that optimizes execution while minimizing long-term costs. Quality producers like Shengde combine progressive generation innovation with thorough quality control to guarantee reliable product execution that meets worldwide guidelines and surpasses client desires.