To secure your priceless goods and equipment, the finest PE tarps for truck and storage protection combine affordability, weather resistance, and durability. The exceptional waterproof protection, UV resistance, and rip strength that commercial applications need are provided by premium polyethylene tarpaulin sheets. The multi-layer design, heat-sealed seams, and reinforced grommets of professional-grade tarp material guarantee long-lasting performance under demanding conditions.

Introduction

Choosing the appropriate protective covering is crucial for preventing expensive damage while storing equipment in storage facilities or safeguarding precious goods during transit. Modern polyethylene technology has greatly advanced heavy-duty tarp options, offering outstanding performance in a variety of applications. To preserve cargo integrity, the international transportation and logistics sector mostly depends on high-quality waterproof tarp systems. Reliable tarp cover solutions are becoming more and more necessary for anything from agricultural items that need moisture protection to construction materials that are exposed to severe weather. Expert fleet managers are aware that spending more money on high-quality tarp sheets immediately results in fewer insurance claims, happier customers, and more operational effectiveness. A high-quality tarp material must be able to endure mechanical stress from loading operations, extensive UV exposure, and drastic temperature changes. The best solutions combine precise production methods with cutting-edge polymer chemistry to provide reliable performance across thousands of usage cycles.

Essential Selection Criteria for Premium Protection

Selecting the best protective covers requires carefully weighing a number of important performance criteria, particularly when evaluating PE tarps for durability, flexibility, and cost effectiveness. The weight-to-strength ratio is the most important factor since drivers want their cars to be as durable as possible without putting undue strain on them. Using cutting-edge material technology, quality tarp providers create products that strike a compromise between these conflicting demands. Long-term value is determined by UV resistance characteristics, especially for applications requiring prolonged outdoor exposure. Specialized additives are used in professional-grade tarpaulin fabric to stop polymer deterioration in the presence of strong sunlight. According to testing guidelines, materials must retain their structural integrity after being exposed to accelerated weathering for 1,000 hours. Usability and lifespan are directly impacted by grommet spacing and reinforcing. While unique arrangements meet particular application needs, standard layouts incorporate reinforced connection points every 18 inches throughout the perimeter. Double-stitched hems provide extra stability for crucial applications, and heat-sealed edges remove weak spots that often break under stress.

Top-Rated Solutions for Commercial Applications

Heavy-Duty Multi-Layer Construction

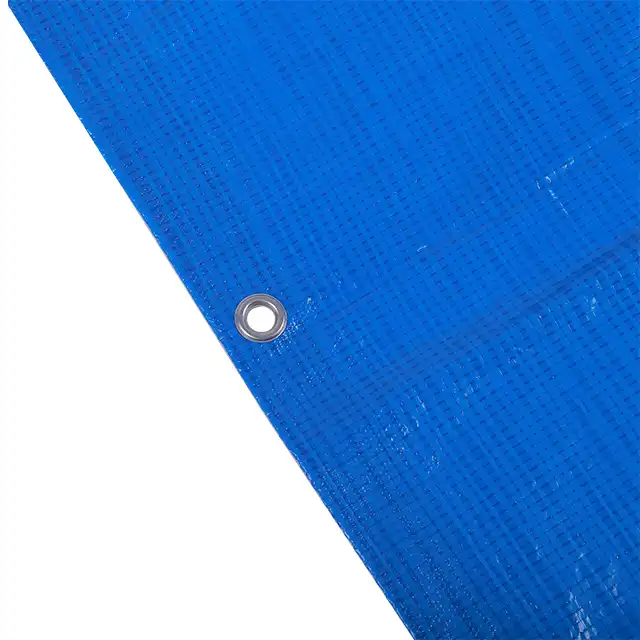

Multi-layer polyethylene systems, which mix woven fabric cores with extruded polymer coatings, are becoming more and more popular among professional transportation businesses. In frigid weather, these cutting-edge tarp sheets provide outstanding rip resistance without sacrificing flexibility. Dimensional stability is provided by the woven foundation, limiting stretching that might reduce the efficiency of covering. High-temperature lamination is used in manufacturing operations to fuse layers without forming brittle surfaces. Standardized peel tests are used in quality control procedures to confirm adhesion strength, guaranteeing uniform performance across manufacturing batches. Thin regions that can break under stress are avoided by keeping thickness fluctuations within strict limits. Operators can swiftly determine the proper covers for certain applications with the use of color-coding systems. Silver surfaces reflect heat for cargo that is sensitive to temperature, whereas blue tarp designs usually imply a general-purpose application. Custom colors enhance inventory management effectiveness and satisfy company branding needs.

Reinforced Edge Systems

Modern systems have numerous layers of protection around perimeters where stress accumulates, demonstrating the considerable advancements in edge reinforcement technology used in PE tarps. By dispersing loading pressures across larger regions, rope-reinforced edges lessen localized stress that leads to early failure. Stitching that might deteriorate with repetitive stress is eliminated by heat-welded fabrication. For maritime applications, grommets may be made of corrosion-resistant stainless steel or regular brass. Different tie-down techniques are supported by spacing intervals; tighter spacing offers a more secure connection for valuable goods. Each grommet has reinforcement patches around it to prevent tear-out under dynamic stress situations, which are typical during transit. Professional installation methods guarantee that high-quality edge systems operate at their best. While proper overlap at corners removes water penetration pathways, proper tensioning avoids flutter that results in fatigue damage. Through proper handling techniques, training programs assist operators in maximizing service life.

Specialized Coating Technologies

Certain performance needs in a variety of applications are addressed by advanced coating formulations. Proprietary polymer mixes are used in waterproof tarp systems to provide total moisture barriers while maintaining flexibility. Molecular networks that are resistant to puncture and provide regulated flexibility are produced via cross-linking chemistry. When moving delicate items, anti-static treatments lessen the risk of fire and stop dust buildup. Static charge is securely dissipated by conductive additions without sacrificing insulating qualities. Testing procedures confirm that electrical characteristics satisfy industrial safety requirements for the transportation of hazardous materials. Surface texturing facilitates drainage to avoid water buildup and increases grip for a solid installation. By directing moisture toward drainage points, embossed patterns avoid pooling, which adds needless weight and strain. For reusable applications, texture depth strikes a compromise between ease of cleaning and drainage efficiency.

Global Market Characteristics and Regulations

Minimum performance requirements for cargo protection systems are set by international transportation laws. Directives from the European Union provide standards for material composition and testing procedures that guarantee environmental compatibility. North American standards place a strong emphasis on safety performance in severe weather, which is typical of continental transportation routes. Product selection varies by area and is influenced by cultural preferences. Compact storage and quick deployment qualities that work in urban settings with limited space are given priority in Asian markets. Applications in Africa place a strong emphasis on resilience in the face of severe heat and UV radiation. Cost-effectiveness without sacrificing necessary protective features is valued by South American consumers. Demand for adaptable systems that support many applications is driven by emerging markets. Opportunities for providers who can provide reliable quality at affordable pricing are created by economic growth. Since transportation costs have an impact on overall ownership costs, local distribution networks are becoming more and more significant.

Professional Purchasing Recommendations

While maintaining uniform quality across fleet operations, volume purchase techniques may drastically save expenses per unit, particularly when sourcing PE tarps in bulk for consistent protection and cost efficiency. Annual agreements with reputable tarp suppliers assure supply and price consistency during seasons of high demand. Detailed performance criteria should be included in quality standards instead of generalizations that permit subpar replacements. For high-quality protection systems, maintenance plans increase return on investment and prolong service life. Frequent cleaning gets rid of accumulated material that might lead to abrasion damage. When covers are not in use, proper storage reduces UV exposure, and well-organized inventory procedures guarantee that older stock rotates as it should. Assessing supplier performance and determining the best replacement intervals are made easier with performance monitoring. Future purchase choices are guided by thorough records of service life under varied scenarios. Disposal costs and environmental factors that influence total ownership costs should be included in cost analyses.

Industry Trends and Summary

As environmental restrictions become more stringent worldwide, purchase choices are increasingly influenced by sustainable manufacturing processes. Customers who care about the environment are drawn to recyclable materials and less packaging waste. Thinner materials with comparable performance and lower resource consumption are made possible by advanced polymer chemistry. Automated deployment systems and condition monitoring are possible with smart technology integration. RFID tags make it possible to automate maintenance scheduling and inventory monitoring. Embedded sensors that monitor cargo conditions and notify operators of any issues might be part of future advancements.

Conclusion

Selecting optimal protective coverings requires balancing performance requirements with budget constraints while considering long-term operational needs, especially when evaluating PE tarps for cost-effective durability and reliable weather protection. Quality polyethylene tarpaulin systems deliver exceptional value through extended service life and reliable protection. Advanced manufacturing techniques continue to improve performanceintaining the cost-effectiveness that commercial applications require.

Investment in superior tarp material pays dividends through reduced cargo damage, improved operational efficiency, and enhanced customer satisfaction. Professional-grade solutions from established manufacturers provide the consistency and reliability that successful transportation operations demand. The global market offers numerous options, making careful evaluation essential for optimal results.

Frequently Asked Questions

Q1: How do I determine the correct tarp size for my truck?

A: Measure your truck bed length, width, and maximum load height, then add 2-3 feet to each dimension for proper overlap. Standard tarp sizes include 8x10, 10x12, and 12x16 feet, though custom sizes accommodate specific requirements. Consider cargo type and securement method when calculating coverage needs.

Q2: What thickness specification provides optimal durability?

A: Heavy-duty applications typically require 12-16 mil thickness for reliable performance. Lighter applications can use 6-10 mil materials effectively. Thickness alone doesn't determine quality - construction method and material composition significantly impact durability and performance characteristics.

Q3: How should I maintain my tarps for maximum service life?

A: Clean tarps with mild soap and water after each use, paying attention to grommet areas where debris accumulates. Store in dry locations away from direct sunlight. Inspect regularly for small tears that can be repaired before they become major problems. Avoid dragging across rough surfaces.

Partner with Shengde for Superior Tarp Solutions

Shengde's two decades of manufacturing excellence deliver the reliability your operations demand. Our ISO 9001:2015 certified facility produces over 100 tons daily using advanced Korean water-jet looms and precision coating systems. Trusted partnerships with UNHCR, IOM, and UNICEF demonstrate our commitment to quality that performs under the most demanding conditions. Whether you need standard configurations or custom specifications, our engineering team can develop solutions that meet your exact requirements. Ready to experience the Shengde advantage? Contact us at info@shengdetarp.com and discover why leading companies worldwide choose our PE tarp solutions for their critical protection needs.