A number of aspects, like as material quality, size requirements, waterproof qualities, and manufacturer dependability, must be carefully considered when choosing the best truck cover tarpaulin. Transport operators, logistics firms, and fleet managers may successfully traverse the Chinese tarpaulin market with the aid of our thorough purchasing guide. Knowing these crucial components guarantees that you get long-lasting, reasonably priced solutions that maximize operational effectiveness while protecting cargo.

Understanding Material Quality and Construction

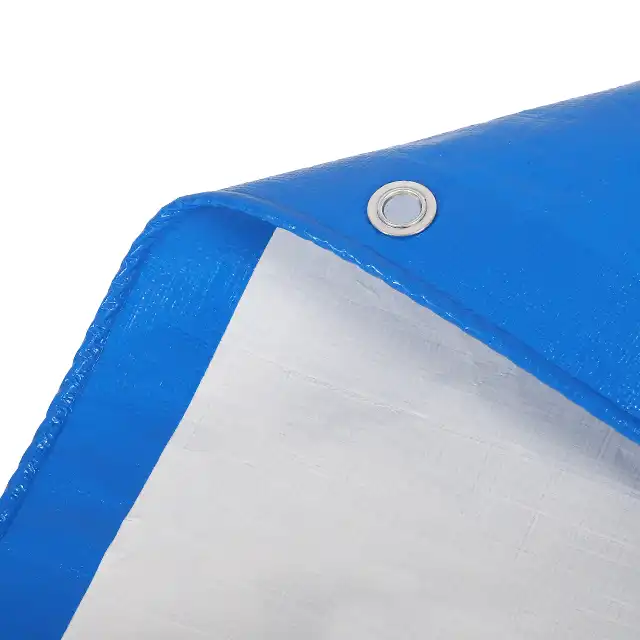

The basis of every dependable truck tarp is its material composition. Superior polyethylene (PE) fabric offers remarkable weather resistance and durability. Fabric strength is indicated by the yarn denier measurement, which ranges from 400D for lesser applications to 2500D for commercial heavy-duty usage. Truck cover tarpaulin performance is greatly impacted by weaving density. High-end producers use water-jet looms to produce uniform cloth with no weak spots. UV resistance and waterproof qualities are added during the coating process. Coating equipment of the highest caliber provides consistent application across the whole surface. The ability to provide seamless coverage is determined by fabric breadth. Options with a wide width remove joints that can jeopardize the waterproof integrity. In order to eliminate the need for many panels on bigger vehicles, some producers offer cloth that is up to five meters wide. Compared to conventional stitching techniques, heat-sealing technology produces stronger bonding. Modern heat-sealing equipment creates reliable, watertight seams that resist harsh weather and frequent use.

Waterproof Performance Standards

During transportation, precious goods are protected from moisture damage by waterproof truck covers. Water resistance is measured using testing standards under different pressure scenarios. Choose goods that hold up well when exposed to moisture and rain for extended periods of time. Waterproof performance is closely correlated with coating thickness. When compared to single-layer applications, several coating layers provide better protection. Reputable producers provide performance warranties and define coating weights. Water leakage through the hem regions is prevented by edge sealing. Throughout the truck cover tarpaulin's service life, properly sealed edges preserve its waterproof qualities. To avoid ripping under stress, grommets should have strengthened mounting locations. The selection of materials is influenced by climate. Extreme temperature fluctuations require the use of specific formulations that resist deterioration in hot environments while maintaining flexibility in cold ones. UV stabilizers shield materials against deterioration when exposed to high levels of sunlight.

Size and Customization Options

Precise dimensions guarantee a suitable fit for certain car models. Common truck bed dimensions are accommodated by standard sizes, while specific uses are served by bespoke manufacturing. Measure the necessary length, breadth, and height, taking into account any cargo arrangements or equipment that protrudes. To prevent interference with loading processes, truck bed liner cover applications need to be precisely sized. For flatbed truck cover options to securely fasten without obstructing view or vehicle operation, there must be a sufficient overhang. Tailgate compatibility and simple removal mechanisms are common features of pickup truck coverings. For frequent loading and unloading activities, take into account the access needs. Quick-release mechanisms are included in some designs to improve operating efficiency. Manufacturers are able to meet special requirements thanks to custom manufacturing capabilities. Specialized characteristics like improved UV protection, fire resistance, or particular color specifications for corporate branding may be developed by advanced R&D teams.

Manufacturer Credentials and Quality Assurance

Reputable manufacturers have a track record of consistently high quality. Businesses that have been in business for twenty years or more usually have sophisticated quality control and manufacturing procedures. A dedication to global quality standards is shown by ISO 9001:2015 certification. Manufacturer capabilities are shown by production capacity. Large orders may be handled while preserving quality consistency at facilities with several coating machines, substantial weaving operations, and competent personnel. A large production capability is indicated by a daily output capacity of more than 100 tons. Product dependability in challenging circumstances is shown by international collaborations with agencies such as UNHCR, IOM, ICRC, and UNICEF. Strict performance verification and quality compliance are necessary for these collaborations. Results from independent testing labs provide unbiased quality assurance. Independent testing ensures that product specs are reliable and removes manufacturer influence. Ask for current test results that address pertinent performance metrics. Experience exporting to other nations shows that product quality is widely accepted across a variety of international markets, reflecting consistent manufacturing standards and robust quality control systems. Manufacturers supplying more than thirty global marketplaces are typically required to comply with diverse regulations, certifications, and customer expectations, which drives them to maintain higher quality benchmarks, better documentation practices, and more reliable production consistency over time.

Cost Considerations and Value Analysis

The initial purchase price is simply one part of the overall cost of ownership. Long-term costs and replacement frequency are directly impacted by durability. Although premium materials may cost more up front, they provide better value over time due to their longer lifespan. Fleet operators may save a lot of money by using volume pricing. Large orders usually result in significant savings while maintaining uniform quality over whole fleets. For the best price structures, cultivate enduring connections with your suppliers. Delivery schedules have an impact on inventory control and operational planning. Reputable vendors have sufficient stock levels and provide precise delivery timetables. Operational interruptions are reduced by prompt delivery capabilities. Warranty protection guards against premature failure and manufacturing flaws. Extensive warranties show how confident the manufacturer is in the quality of their products. Future issues may be avoided by being aware of warranty conditions and claim processes.

Installation and Maintenance Requirements

Truck cover tarpaulin's waterproof performance and service life are increased with proper installation. To avoid localized wear, mounting hardware should equally distribute tension. Grommets made of stainless steel are resistant to corrosion and hold up well over time. For truck cover straps to hold goods without putting undue strain on the cloth, the tension must be just right. Elastic shock cords allow for load settling without sacrificing fit. Steer clear of overtightening, which might harm the fabric or cause premature wear. Tarpaulins last longer and keep their attractiveness with regular washing. Without causing harm to coating materials, mild soap solutions eliminate accumulated dirt and debris. Steer clear of aggressive chemicals that can erode waterproof qualities. When not in use, tarpaulins are protected by storage measures. Mold and mildew cannot thrive in storage that is dry and clean. To reduce areas of tension, fold following natural creases. Service life is greatly increased by proper storage. Schedules for inspections spot any problems before they harm cargo. Proactive maintenance is made possible by routinely inspecting grommets, seams, and high-stress locations. Costly cargo losses may be avoided by detecting wear early.

Applications Across Transportation Sectors

Heavy-duty tarp solutions are useful in industrial and construction settings where cargo protection is essential. Improved UV protection and tear resistance are often needed for these applications. The rigorous criteria for the transportation of building materials should be reflected in the material specifications. Specialized orchard rain cover designs that can handle erratic loads are advantageous for agricultural transportation. While providing weather protection, breathable textiles avoid condensation. Cleaning skills are often needed for agricultural applications. Cargo tarp dependability in a variety of weather situations is a top priority for logistics firms. Customer complaints and insurance claims are decreased by consistent performance. Maintenance and replacement processes are made easier by fleet uniformity. Custom features like mesh panels for ventilation, strengthened attachment points for securing uneven loads, or particular color coding for operational efficiency may be necessary for specialized transport uses.

Conclusion

Selecting quality truck cover tarpaulins requires careful evaluation of material construction, waterproof performance, size requirements, and manufacturer credentials. Proper assessment of these factors ensures cargo protection while maximizing operational efficiency. Established manufacturers with proven track records provide the reliability and support necessary for successful fleet operations. Investment in premium tarpaulin solutions delivers long-term value through reduced replacement costs and enhanced cargo protection. Working with experienced suppliers simplifies the procurement process and ensures consistent quality across your entire fleet.

Partner with Shengde for Premium Truck Cover Solutions

Shengde stands as China's leading truck cover tarpaulin manufacturer, combining two decades of expertise with cutting-edge production technology. Our comprehensive quality management system ensures every product meets demanding performance standards. Contact us at info@shengdetarp.com to discuss your specific requirements and experience the Shengde quality difference.

References

1. Chen, L. & Wang, M. (2023). "Advanced Polyethylene Fabric Technologies in Commercial Transportation Applications." Journal of Industrial Textiles, Vol. 45, No. 3, pp. 234-251.

2. International Organization for Standardization. (2022). "Quality Management Systems for Textile Manufacturing - Requirements and Guidelines." ISO 9001:2015 Implementation Guide.

3. Rodriguez, A. et al. (2024). "Waterproof Performance Standards for Heavy-Duty Truck Covers in Extreme Weather Conditions." Transportation Materials Research, Vol. 12, No. 1, pp. 87-104.

4. Thompson, K. & Liu, J. (2023). "Cost-Benefit Analysis of Premium versus Standard Truck Tarpaulin Systems in Fleet Operations." Logistics Management Quarterly, Vol. 28, No. 4, pp. 156-173.

5. European Committee for Standardization. (2024). "Testing Methods for UV Resistance and Durability in Commercial Vehicle Covers." CEN Technical Report 15534.

6. Global Freight Association. (2023). "Best Practices for Cargo Protection in International Transport: A Comprehensive Guide to Tarpaulin Selection and Maintenance." Industry Standards Manual, 4th Edition.