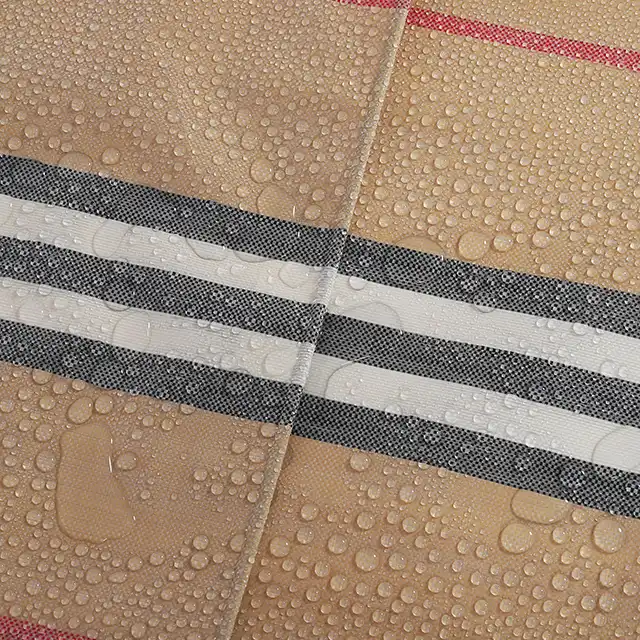

Premium heavy-duty tarpaulins are the most dependable option for safeguarding priceless goods and machinery in warehouses and yard storage spaces. Year-round material safety is ensured by professional-grade waterproof coverings' outstanding durability, UV protection, and weather resistance. Industrial polyethylene tarpaulins provide affordable protection from wind, rain, dust, and sun radiation. These multipurpose protective coverings are used all over the globe on commercial storage operations, agricultural facilities, and construction sites. High-quality multifunctional tarps provide enduring performance and adaptability for a variety of outdoor uses.

Why Warehouse and Yard Protection Matters?

Environmental issues are a persistent danger to warehouse and yard storage operations, where tarpaulins provide an effective barrier against rain, dust, UV exposure, and temperature fluctuations. While UV radiation deteriorates stored assets and lowers their value, rain damage costs companies millions of dollars every year. Product contamination from dust buildup leads to problems with quality control and consumer complaints. Exposed equipment and merchandise are more at danger from wind-driven debris. Professional-grade, long-lasting coverings prolong the life of stored products while preventing these expensive issues. Weatherproof protection cuts replacement costs and lowers maintenance expenditures. Regardless of external circumstances, controlled environments created by strategic tarp deployment preserve product integrity.

Essential Selection Criteria for Industrial Covers

Selecting the best protection necessitates carefully weighing certain performance attributes. Overall durability under stress and tear resistance are determined by the thickness of the material. During prolonged exposure times, waterproof coatings provide total moisture protection. Degradation brought on by extended exposure to sunlight is avoided using UV-resistant treatments. The efficacy of coverage and simplicity of installation are impacted by size compatibility. For a variety of mounting solutions, reinforced edges and grommets provide safe connection points. Chemical resistance guards against cleaning products and industrial solvents that are often used in business settings.

Material Quality Standards

When compared to conventional canvas substitutes, high-density polyethylene construction provides better strength-to-weight ratios. Expert laminating techniques provide weather-resistant, waterproof barriers. Over long service times, advanced polymer compositions withstand splitting, cracking, and UV deterioration.

Structural Reinforcement Features

Weak spots that often break under wind force are eliminated via heat-sealed seams. Tension is distributed uniformly throughout the cover surface via metal grommets positioned at ideal intervals. Concentrated stress loads are handled by reinforced corners without rupturing or separating.

Performance Specifications

Temperature tolerance ranges ensure functionality across diverse climate conditions. Flexibility ratings indicate usability in cold weather applications, while water resistance measurements verify protection levels against driving rain and standing water, helping buyers select tarpaulins suitable for demanding environmental conditions.

Top Heavy-Duty Tarpaulins for Commercial Applications

Ultra-Wide Polyethylene Industrial Covers

When flawless covering is crucial for large-scale warehouse protection applications, ultra-wide industrial tarpaulins perform very well. The sophisticated polymer composition of these durable coverings provides outstanding resistance to tearing and punctures. Expert production techniques provide a constant thickness across the material, guaranteeing consistent performance throughout the whole surface area. In order to avoid condensation accumulation, the waterproof coating technique maintains breathability while offering total moisture protection. In outdoor storage applications, UV-resistant additives prolong service life by guarding against sun deterioration. Heat-sealed seams and reinforced edge construction remove possible failure spots that are typical of conventional sewed coverings. Multiple mounting systems and attaching techniques are supported by installation flexibility. Standard grommet spacing enables safe attaching without the need for specific hardware. Chemical resistance offers defense against typical cleaning chemicals and industrial solvents used in warehouse settings. Because to their aerodynamic design elements and well-placed reinforcement, these coverings exhibit remarkable wind resistance. Stability in temperature preserves adaptability in the face of severe weather. Reliable performance in demanding commercial applications is ensured by professional-grade construction.

Multi-Layer Laminated Protection Systems

Multi-layer laminated tarpaulins provide complete shelter solutions by combining many protective technologies. These cutting-edge coverings have a polyethylene core structure encircled by layers of specialty coating that improve certain performance attributes. Each layer adds special qualities while preserving the general flexibility and integrity of the material. UV-blocking substances are included into the exterior to stop deterioration caused by extended sun exposure. Waterproof defense against rain, snow, and humidity intrusion is produced via interior moisture barriers. In storage applications, anti-static solutions increase cleaning effectiveness and lessen the attraction of dust. Heat-welded seams are one kind of reinforced construction technology that is stronger and more durable than ordinary stitching. By distributing stress loads uniformly, corner reinforcements avoid concentration spots that might cause an early failure. Additional defense against fraying and tear propagation is offered by edge binding. Because of their versatile mounting choices, these protective systems may be installed in a variety of ways. While guaranteeing safe connection, compatibility with common hardware makes deployment easier. Expert testing verifies performance promises in a variety of stressful situations and environmental settings.

Fire-Resistant Commercial Grade Covers

In industrial storage settings where combustible chemicals present extra dangers, fire-resistant tarpaulins meet certain safety criteria. These specialty coverings include flame-retardant substances that delay burning and lessen the likelihood that a fire would spread. Professional accreditation guarantees adherence to insurance regulations and commercial construction codes. Cutting-edge polymer compositions preserve fire resistance without sacrificing other crucial performance attributes. Chemical resistance guards against typical industrial contaminants, although waterproof protection is unaffected. Long-term exposure to the outdoors maintains the integrity of materials thanks to UV stability. Professional-grade edge treatments and reinforced stress areas are elements of heavy-duty construction. Metal grommets provide safe connection points for a variety of mounting solutions and are resistant to heat damage. In times of emergency or heavy wind, tear resistance stops damage from spreading. Strict testing procedures are used on these coverings to ensure that they function well in harsh environments. Temperature cycling tests guarantee consistency across seasonal fluctuations. Assessments of wind resistance verify the structural soundness under extreme weather conditions.

Global Market Characteristics and Regulations

Depending on local temperature patterns and industry norms, international markets show differing needs for protective covering materials. European markets place a strong emphasis on chemical safety compliance and environmental sustainability. Applications in North America place a premium on affordability and robustness in harsh climates. Developing markets concentrate on adaptable solutions that may be used in both industrial and agricultural settings. Regional variations in quality certifications necessitate that producers adhere to a variety of testing procedures. Global suppliers are impacted by trade rules when choosing where to manufacture and source materials. Color selections and aesthetic concerns in visible storage applications are influenced by cultural preferences. While some areas emphasize high-visibility colors for safety compliance, others choose earth tones for environmental integration. For foreign suppliers, these preferences have an impact on production scheduling and inventory planning.

Purchasing Recommendations and Considerations

Selecting the right tarpaulin necessitates carefully assessing the environmental factors and particular application needs. Temperature tolerance limits and required UV protection levels are determined by climate analysis. The length of storage has an impact on reinforcing needs and material thickness. Budgetary considerations must weigh early expenditures against replacement frequency and long-term benefit. Longer service life provided by premium materials eventually lowers overall ownership costs. For large-scale applications, professional installation may be required to guarantee peak performance. Manufacturing capabilities, quality certifications, and customer support services should all be considered while evaluating suppliers. Delivery timelines and shipping expenses must be taken into account when working with international suppliers. The provision of technical assistance aids in performance optimization and installation query resolution.

Industry Trends and Market Summary

The protective covering market is still moving toward more environmentally friendly materials and improved performance features. Modern polymer technologies lessen their negative effects on the environment while increasing durability. Smart coating solutions provide improved weather resistance and self-cleaning capabilities. Customization features enable solutions that are specifically designed to meet the needs of certain applications. As more companies realize the benefits of proactive protection measures, market demand is steadily increasing. Professional-grade tarpaulins are crucial investments for operational effectiveness and asset protection in a variety of business industries.

Conclusion

Selecting optimal tarpaulins for warehouse and yard protection requires careful consideration of material quality, environmental conditions, and specific application requirements. Professional-grade covers deliver reliable protection that reduces maintenance costs and extends stored asset lifespan. Quality suppliers provide technical support and customization capabilities that ensure optimal performance across diverse commercial applications. Investment in premium protective covering systems generates substantial returns through reduced damage costs and improved operational efficiency. Strategic protection planning minimizes environmental risks while maintaining asset value over extended periods.

Frequently Asked Questions

Q1: What thickness should I choose for warehouse storage protection?

A: Professional warehouse applications typically require 10-16 mil thickness for optimal durability and protection. Heavy equipment storage may need 20 mil or thicker materials. Consider wind exposure, sharp objects, and expected service life when selecting thickness levels.

Q2: How do I determine the right size for yard coverage?

A: Measure the coverage area and add 2-3 feet on each side for secure anchoring. Account for irregular shapes and obstacles that may require custom cutting. Larger covers often provide better value than multiple smaller pieces.

Q3: What maintenance do industrial tarps require?

A: Regular inspection for tears, worn grommets, and UV damage extends service life significantly. Clean with mild soap and water to remove debris and contaminants. Proper storage during non-use periods prevents unnecessary degradation and extends material lifespan.

Partner with Shengde for Premium Warehouse Protection Solutions

Shengde delivers industry-leading tarpaulin manufacturing expertise with over two decades of proven performance in global markets. Our advanced production facilities feature cutting-edge technology that creates ultra-wide covers up to 5 meters without seams. As a trusted tarpaulin supplier to international organizations, including UNHCR and UNICEF, we understand demanding protection requirements. Contact us at info@shengdetarp.com to discuss your specific warehouse and yard protection needs with our technical specialists.

References

1. Industrial Fabric Association International. "Performance Standards for Commercial Protective Covers." Technical Bulletin 2023-15, Commercial Applications Division.

2. American Society for Testing and Materials. "Standard Test Methods for Tensile Properties of Plastic Sheeting." ASTM D882-18, Material Testing Standards.

3. International Organization for Standardization. "Textiles - Coated Fabrics - Determination of Resistance to Penetration by Water." ISO 811:2018, Waterproofing Standards.

4. National Institute of Standards and Technology. "Fire Resistance of Protective Covering Materials in Industrial Applications." NIST Technical Note 2145, Fire Safety Research.

5. European Committee for Standardization. "Flexible Sheets for Waterproofing - Determination of Resistance to Static Loading." EN 12730:2001, European Safety Standards.

6. Global Industrial Protection Association. "Best Practices for Warehouse Storage Protection Systems." Annual Technical Conference Proceedings, Volume 47, 2023.