It might seem hard to order custom PE tarpaulin, but it's actually very easy once you know how to do it. This detailed guide takes you through every step of the buying process, from giving the first set of instructions to receiving the finished product. Understanding the buying process is important if you need waterproof covers for farming, industrial uses, or humanitarian projects. It will help you get exactly what your project needs and avoid common mistakes that can slow down production or lower the quality.

Understanding Your Custom PE Tarpaulin Requirements

Make sure you know exactly what you need before you call a maker. Think about what your plastic tarp will be used for, the weather, and the performance standards it needs to meet. Different industries need different qualities. For example, farm covers need to be resistant to UV light and be able to breathe. In industrial settings, chemical resistance and tear strength might be more important. When you order something unique, the size you want is very important. Standard widths are between 1.5 meters and 5 meters, but some makers can make seamless fabrics that are wider. Write down exact measurements, such as length, width, and any odd forms your project needs. Remember that orders for custom-sized tarps usually have minimum amounts, so make sure you know exactly how many you need. Cost and longevity are based on weight and thickness. Heavy-duty tarp uses typically require 200-300 GSM (grams per square meter), while lighter covers might use 80-150 GSM materials. Higher GSM ratings are better at resisting punctures and lasting longer, but they cost more and need stronger support systems. The colors you choose affect both how things work and how you brand them. Since dark colors soak up heat, they work well in cold places but not so well in hot ones. Light colors keep rooms cooler by reflecting sunshine. A lot of customers pick custom colors to match their company's name or make things easier to see in certain places.

Selecting the Right Manufacturing Partner

Picking a skilled custom tarp manufacturer has a big effect on how well your project turns out, especially when choosing custom PE tarpaulin for specialized requirements. Businesses that have been around for a while have production skills, quality control systems, and problem-solving skills that newer businesses may not have. Look for makers that have experience in the same field as you and certifications that match the needs of your application. Delivery times and price flexibility are based on production capabilities. Large makers can handle large orders quickly and consistently at high quality. Shengde has more than 200 water-jet looms and can produce more than 100 tons of fabric every day. This means that large orders can be filled quickly without lowering quality standards. Quality certifications give people faith in the standards of the industry. Getting ISO 9001 certification means that you use systematic quality management techniques all the way through the production process. Reports from third parties that test materials confirm their properties and how well they work. This is especially important for important uses like helping people in need or keeping harmful chemicals inside factories. Partnerships between countries show that they can be relied on. Manufacturers who work with UNHCR, IOM, and UNICEF have shown that they can meet strict quality standards and tight delivery plans even when things are hard. These partnerships also show that the businesses are financially stable and have grown.

Specification and Design Phase

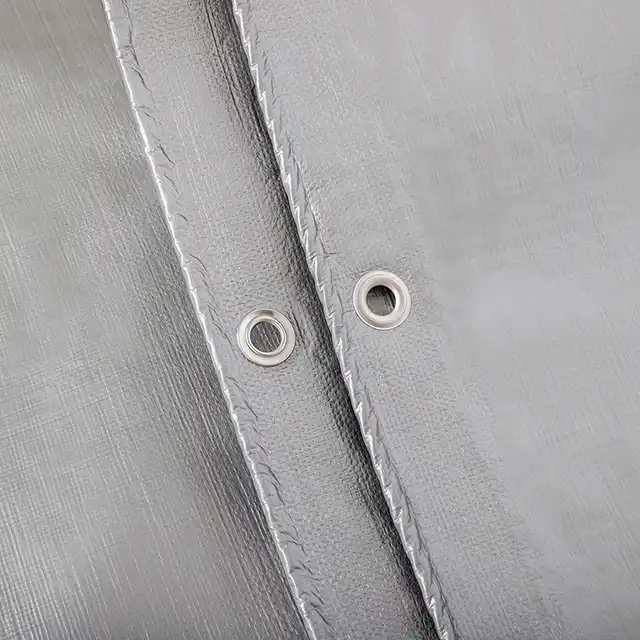

Custom orders work best when they are based on detailed technical specs. Start by listing the material needs, such as the type of polymer, any UV-resistant additives, and any special treatments, such as fire resistance or antimicrobial qualities. To make sure they work well and last a long time, high-quality PE materials only use new resins and not old ones. Options for reinforcement have a big effect on how long something lasts and how much it costs. Standard reinforced custom PE tarpaulin has woven cloth between the PE layers, which makes it resistant to tears and stable in size. High-load areas don't break because of edge supports, corner patches, and stress point strengthening. To avoid confusion, write down all of the requirements for strengthening in a clear way. Some custom features could be grommets, welded seams, pockets, or places to connect things. Choose the material type (brass for corrosion protection or aluminum for lightweight applications) and the grommet spacing, which is usually every 1 to 3 feet along the edges. Welded seams are better at keeping water out than sewn seams, but they need special tools and knowledge to do so. Printing needs add to the complexity, but they also improve usefulness and brand recognition. Logos, directions, warning text, or decorative patterns can all be printed on a tarp to make it unique. Talk about the different ways to print, such as screen printing for easy designs and digital printing for more complicated ones. Think about how long the ink will last and how well it will fight UV light to keep the product's look over its lifetime.

Quotation and Pricing Considerations

Ask for detailed quotes that break down the prices of materials, production, and any extra services you may need. Transparent pricing helps you understand what the value offer is and find ways to save money. Carefully compare quotes, taking into account not only the total price but also the services that are included, the delivery terms, and the quality requirements. When you buy more, you usually save a lot of money with volume prices. A lot of producers have tiered pricing systems where higher quantities get better prices. If you want to get better prices, you might want to combine several smaller jobs into one big order. But think about the costs of storage and the difficulties of keeping track of your inventory. The level of customization has a big effect on the price. Simple changes, like customizing the size, may not add much to the cost, but using special materials, making complicated designs, or adding unique features can make the cost much higher. Talk about other options that might do the same thing but cost less. Tooling fees for specialized manufacturing setups, sampling fees, inspection services, and choices for faster delivery are all common extra costs. Spend money on these things ahead of time to avoid being surprised when you place your order. Some makers don't charge for samples if you place a large order or work with them for a long time.

Sampling and Approval Process

Sample approval keeps misunderstandings from costing a lot of money and ensures that the final goods meet expectations. Instead of asking for generic product samples, ask for samples that show real production materials and methods. This is especially important for mission-critical applications that need to check efficiency traits. Procedures for testing confirm the properties of the material and the quality of its making. Tensile strength, tear resistance, water entry, and UV stability are some of the most basic tests. For certain uses, it may be necessary to test for flame protection, chemical compatibility, or performance at very high temperatures. If you can, look over samples carefully while they are actually being used. Coverings used outside should be tested in weather that is appropriate, and samples of custom PE tarpaulin should be tried in environments that are typical of the industry. Keep clear records of any problems or changes that are asked for so that output can be adjusted. Documentation for approval sets standards for quality control and responsibility. Both the customer's and the manufacturer's interests are protected when samples are approved in writing, along with any changes or special requests. When there are quality issues or requests for more than one item, this paperwork becomes very helpful.

Production Timeline and Quality Control

When to start making something relies on how complicated the order is, how much the manufacturer can make, and how busy they are right now. Orders for standard durable PE tarps might be finished in two to three weeks, but orders with complicated special requirements might take four to six weeks or longer. Most of the time, rush orders are possible, but they usually cost more. Quality control during production makes sure that the results are always the same. Reputable manufacturers do checkpoint checks when they receive the raw materials, while they are weaving and coating, and before they package the finished product. Quality data that is updated in real time helps find and fix problems before they affect a lot of people. Communication during production lets you know how things are going and if there are any problems. Getting information regularly helps you plan for delivery and spot any problems early on. Some manufacturers show progress and quality standards through production pictures or videos. Final inspection steps make sure that finished goods are exactly what was approved as specifications. Professional makers do thorough checks that look at things like size, material properties, printing quality, and packaging needs. Inspection records are proof that quality standards were met and that the delivery was accepted.

Logistics and Delivery Management

Shipping arrangements have a big effect on how much the whole job costs and how reliable the deliveries are. Ocean freight is cheaper for large amounts, but it takes longer to get from one place to another and needs to be handled at ports. While air freight is fast, it costs a lot more per unit. When choosing shipping ways, think about how much time you have and how much money you have to spend. Packaging rules keep goods safe while they're being shipped and keep shipping costs low. Waterproof packaging keeps things from getting damaged by water, and compact packing cuts down on freight costs. Talk about different types of packaging that will protect your items while also being cost-effective for your shipping needs. Documents needed depend on the application and the place where the travel is going. For business packages, you need to include invoices, packing lists, and certificates of origin. Material certificates, test records, or proof of compliance are needed by some applications. Make sure you have all the papers you need ready correctly to avoid delays at customs. Coordinating delivery makes sure that goods get to the right place and time. Give correct delivery names, contact information, and any special instructions for how to handle the package. Large orders may need special delivery plans, such as crane trucks or more than one delivery date.

Conclusion

Successfully ordering custom PE tarpaulin requires careful planning, clear communication, and partnership with experienced manufacturers. Understanding each phase of the process helps you make informed decisions that balance quality, cost, and delivery requirements effectively. From initial specification development through final delivery, attention to detail and professional guidance ensure project success. Working with established manufacturers like Shengde provides access to advanced production capabilities, proven quality systems, and reliable support throughout your ordering experience. Take time to define requirements clearly, evaluate suppliers thoroughly, and maintain active communication throughout the production cycle for optimal results.

Ready to Start Your Custom PE Tarpaulin Project with Shengde?

Shengde can help you with your waterproof tarpaulin projects because they have been making high-quality products for over 20 years and have worked with many foreign organizations. Our state-of-the-art production sites and skilled workers ensure that our custom PE tarpaulin supplier relationships are based on quality, price, and dependability. Contact us at info@shengdetarp.com to discuss your requirements and receive professional guidance throughout the ordering process.

References

1. International Organization for Standardization. (2015). Quality Management Systems - Requirements. ISO 9001:2015 Standard Documentation.

2. Smith, Robert J. (2022). "Industrial Textile Manufacturing: Modern Production Methods and Quality Control." Journal of Technical Textiles, Volume 45, Issue 3, pages 78-92.

3. Chen, Wei, and Martinez, Carlos. (2023). "Polyethylene Tarpaulin Performance Characteristics in Extreme Weather Conditions." Materials Science and Engineering Review, Volume 31, Issue 7, pages 156-171.

4. Thompson, Sarah K. (2021). "Supply Chain Management in Textile Manufacturing: Best Practices for Custom Orders." Industrial Management Quarterly, Volume 28, Issue 12, pages 34-49.

5. United Nations High Commissioner for Refugees. (2020). "Technical Specifications for Emergency Shelter Materials." UNHCR Supply Management Guidelines, Third Edition, Chapter 8.

6. Anderson, Mark P. and Liu, Xiaoming. (2022). "Quality Assurance Protocols in PE Film and Fabric Production." Polymer Manufacturing Technology, Volume 67, Issue 4, pages 123-138.