It takes careful material selection, well-placed anchor points, and strengthened tie-down systems to secure a tarp during strong winds. The secret is to use heavy-duty polyethylene tarps with reinforced grommets, tight installation, and many attaching points spaced three to four feet apart around the perimeter to reduce wind resistance. Even in extreme weather, dependable protection is ensured by high-quality anchoring methods, suitable tarp thickness, and UV-resistant materials. Standard anchoring techniques sometimes fail disastrously when wind speeds surpass 25 mph, leaving priceless goods and equipment vulnerable to the weather. Maintaining operational continuity across building sites, agricultural activities, and logistical facilities requires an understanding of aerodynamic principles and the use of professional-grade solutions. The crucial elements that distinguish successful wind-resistant systems from expensive failures are covered in this thorough handbook.

Understanding the Challenges of Securing Tarps in High Wind

Even well-secured coverings might become potentially dangerous due to complicated aerodynamic forces created by high winds. While lateral pressures create material stress that results in fabric splits and grommet failure, wind uplift creates enormous pressure differentials that may lift tarps weighing hundreds of pounds. These dynamic demands change quickly, causing fatigue cycles that gradually erode security measures.

Common Failure Points in Windy Conditions

Corner attachment points, where tension accumulates, are usually the most susceptible locations during high-wind occurrences. The effective surface area exposed to wind pressure is multiplied by balloon effects caused by inadequate grommet spacing, which allows wind to pass through the cover. In residential locations, edge flapping might violate local rules since it speeds up material deterioration and produces noise. Expert installation crews are aware that tie-down strain is greatly impacted by thermal expansion and contraction during weather variations. While excessive tightening in cold weather may lead to catastrophic failure when materials expand in warmer weather, materials that seem secure in calm situations may acquire deadly slack as temperatures drop.

Wind Load Calculations and Material Stress

Wind Load Calculations and Material Stress Engineering calculations show that wind pressure rises exponentially with velocity, making gusts at 40 mph four times more damaging than those at 20 mph. While commercial-grade coverings designed for harsh circumstances may resist gusts above 70 mph when fitted correctly, standard household tarps designated for light-duty applications usually break at persistent winds above 30 mph. Wind resistance capabilities are strongly impacted by the choice of material; woven polyethylene textiles have a higher rip strength than laminated ones. Experienced procurement professionals exploit the predictable patterns in the connection between fabric weight, weave density, and wind resistance to match items with certain environmental criteria.

Key Principles for Securing Tarps Effectively in High Wind

Three key concepts are necessary for high-wind installations to be successful: anchor redundancy, load distribution, and material selection. The basis for dependable performance is provided by heavy-duty polyethylene tarps with reinforced edges and UV stabilization, while an appropriate size guarantees sufficient covering without using too much material that adds needless wind resistance.

Material Selection and Specifications

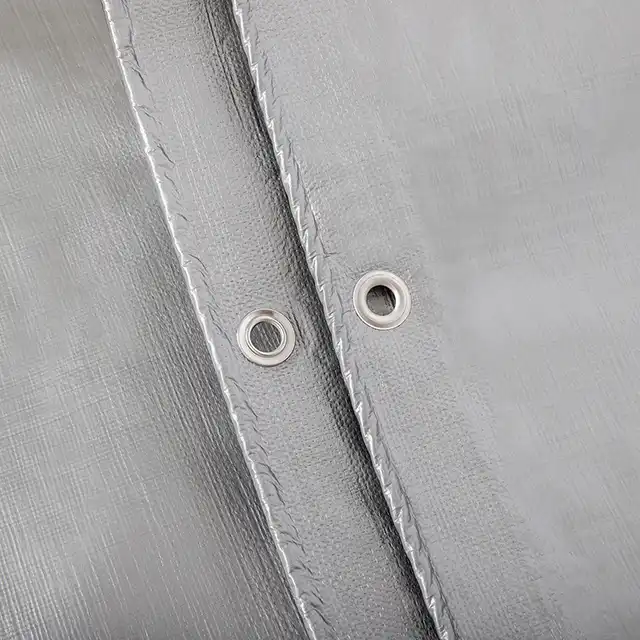

Professional-grade tarp coverings differ from consumer goods in a number of important ways. Fire-retardant coatings are flexible under high temperatures and satisfy industrial safety regulations. During high-stress situations, catastrophic rips that spread over the whole surface are avoided by reinforced hems with double-stitched edges. Products with strategic reinforcing zones and better grommet attachment strength are produced using advanced manufacturing procedures. Through lower replacement costs and increased operational dependability, these technical advancements result in quantifiable performance benefits that outweigh the original expenditure.

Strategic Tie-Down Systems

Instead of concentrating tension at corners, effective securing methods spread wind loads over many attachment points. Expert installations include mid-span anchors for covers longer than 12 feet in either dimension, as well as intermediate tie-down points spaced 24 to 36 inches around the perimeter. The performance of the whole system is greatly impacted by the choice of hardware. While bungee cords give a dynamic reaction to wind gusts, they may stretch beyond their practical limitations during prolonged strong winds. In contrast, ratchet straps allow adjustable tension control and maintain constant pressure over time. Although they are more labor-intensive to install correctly, heavy-duty rope systems with trucker's hitch knots provide dependable performance at reduced prices.

Step-by-Step Guide to Securing a Tarp in High Wind

Thorough site preparation and methodical use of tried-and-true methods are prerequisites for proper installation. In order to safeguard both people and equipment during installation operations, the procedure requires close attention to detail and adherence to safety procedures.

Site Preparation and Initial Setup

Remove any sharp items, trash, and obstructions that can harm the material or make it difficult to secure hardware from the installation area. Examine the cover carefully for any damage that may be present, giving special attention to the edge quality and grommet integrity. Before deployment, fix or replace any flaws to stop failures from spreading under high-wind situations. Anchor points should be positioned in accordance with the intended configuration to provide sufficient load-bearing capability for anticipated wind conditions. Above-ground anchors need structural connections that can sustain uplift pressures of up to 200 pounds per attachment point, while ground stakes need to be inserted at least 18 inches into firm soil.

Systematic Securing Process

Methodically install the cover, first using temporary fasteners to secure the corners before attaching the perimeter. This method enables correct tension adjustment across the whole area and prevents the material from flying during installation.

The following installation sequence ensures optimal results:

- Secure diagonal corners with appropriate tension to eliminate major wrinkles while avoiding over-tightening that could damage grommets

- Install perimeter tie-downs working from corners toward the center of each edge, maintaining consistent spacing and tension.

- Add intermediate anchor points at stress concentration areas and across large unsupported spans.

- Conduct final tension adjustments to eliminate flapping while preserving material flexibility.ty

This systematic approach minimizes installation time while ensuring consistent quality across all attachment points. Regular monitoring during the first 24 hours allows for adjustments as the material settles and environmental conditions change.

Quality Control and Inspection Procedures

Professional installations include documented inspection protocols that verify proper tension, hardware condition, and material integrity. These procedures identify potential issues before they develop into failures and provide baseline conditions for ongoing maintenance activities.

Case Studies: Successful Tarp Securing in High Wind Environments

Real-world applications demonstrate the effectiveness of properly implementing security systems across diverse industries and challenging environmental conditions. These examples illustrate measurable performance improvements and cost savings achieved through professional installation practices.

Construction Site Applications

During the 2023 storm season, a large building project in the Midwest used sophisticated fastening systems, and despite wind gusts surpassing 65 mph on many occasions, there was no weather-related equipment damage. Commercial-grade ratchet straps and designed anchor points were used to hold 16-ounce polypropylene tarps with reinforced grommets placed every 18 inches. When compared to earlier projects that used conventional hardware, project managers claimed that the improved security system avoided weather-related delays by 40%. Because of increased system dependability, manpower needs for maintenance and re-securing operations were considerably reduced, and material replacement prices fell by 75%.

Agricultural and Outdoor Event Success Stories

Professional-grade security solutions have been shown to significantly increase asset preservation in agricultural businesses, safeguarding hay storage and equipment. During the 2024 growing season, a dairy company in Nebraska reported that weather-related feed losses had been eliminated, saving almost $45,000 in replacement expenditures over the previous year. Advanced security measures have also helped outdoor event planners, as shown by fewer insurance claims and increased guest safety in a variety of weather scenarios. Because these applications need dependable performance and quick deployment capabilities, hardware quality and material selection are crucial success factors.

Choosing and Procuring the Right Tarp for Your Needs

System dependability and long-term operating costs are greatly impacted by tarp procurement selections. Making well-informed buying choices that maximize total cost of ownership requires an understanding of the link between material specifications, application needs, and supplier capabilities.

Supplier Evaluation and Quality Standards

Prominent producers uphold extensive quality control procedures that guarantee uniform product performance across manufacturing batches. Third-party testing verification offers independent validation of material requirements and performance claims, while ISO 9001 certification denotes methodical methods to quality management. SENDOW TARPAULIN's state-of-the-art production facilities and stringent quality control procedures are prime examples of industry-leading manufacturing standards. Our 20-year history, which includes collaborations with global institutions like UNHCR, IOM, and UNICEF, shows that we can satisfy exacting requirements for vital applications. Innovations such as ultra-wide products, fire prevention capabilities, and improved waterproof performance that meet a variety of operating needs are the result of the company's research and development investments.

Custom Solutions and Technical Support

Customized items that handle certain operating restrictions and environmental variables are often needed for complex applications. Strong technical skills enable manufacturers to create entirely new solutions or alter existing goods to satisfy specific needs while keeping costs down. Beyond the original product purchase, technical support services such as installation advice, maintenance suggestions, and troubleshooting help provide substantial value. These services guarantee peak performance throughout the course of the product's lifetime and lower deployment risks.

Conclusion

Securing tarps effectively in high wind conditions requires understanding aerodynamic principles, selecting appropriate materials, and implementing systematic installation procedures. Professional-grade solutions provide superior performance compared to standard products, justifying initial investments through reduced maintenance costs and improved operational reliability. Success depends on matching product specifications with application requirements while following proven installation and maintenance practices that maximize system performance over time.

Frequently Asked Questions

Q1: What wind speed requires special securing measures for tarps?

A: Wind speeds exceeding 25 mph require enhanced securing systems with increased tie-down frequency and upgraded hardware. Standard residential installations typically fail at sustained winds above 35 mph, making professional-grade equipment essential for reliable performance in challenging conditions.

Q2: How often should tie-down tension be checked during windy weather?

A: Inspect tie-down systems at least twice daily during high-wind periods, with additional checks after significant weather events. Temperature changes and material settling can affect tension significantly, requiring adjustments to maintain optimal performance and prevent system failure.

Q3: Can standard tarps be modified for better wind resistance?

A: While reinforcement modifications can improve performance marginally, purpose-built heavy-duty tarps provide superior wind resistance through engineered materials and construction techniques. Professional-grade products offer better long-term value through reduced replacement frequency and improved reliability.

Partner with SENDOW TARPAULIN for Superior Wind Protection

SENDOW TARPAULIN delivers engineered solutions specifically designed for high-wind applications across construction, agriculture, and industrial sectors. Our comprehensive product portfolio includes heavy-duty polyethylene covers with reinforced grommets, fire-retardant options, and custom sizing capabilities that meet demanding operational requirements. As a leading tarp manufacturer, we combine advanced manufacturing technology with rigorous quality control systems to ensure consistent performance in challenging conditions.

Our technical team provides expert consultation services that help you select optimal products for your specific wind exposure and operational needs. With over 20 years of manufacturing excellence and proven performance in extreme conditions, we understand the critical importance of reliable protection systems. Contact us at info@shengdetarp.com to discuss your requirements and discover how our premium solutions can enhance your operational resilience while reducing long-term costs.

References

1. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures." ASCE/SEI 7-22 Standards. 2022.

2. National Weather Service Storm Prediction Center. "Wind Speed Classifications and Structural Impact Assessment." NOAA Technical Memorandum. 2023.

3. Industrial Fabric Association International. "Technical Guidelines for Temporary Structure Coverings." IFAI Publication TG-2024. 2024.

4. Construction Industry Institute. "Weather Protection Systems for Construction Sites." Research Report 385-1. 2023.

5. Agricultural Engineering Society. "Crop Protection and Storage Covering Systems." Journal of Agricultural Safety and Health, Volume 29, Issue 3. 2023.

6. International Association of Emergency Managers. "Temporary Shelter and Protection Systems Standards." Emergency Management Guidelines Series. 2024.